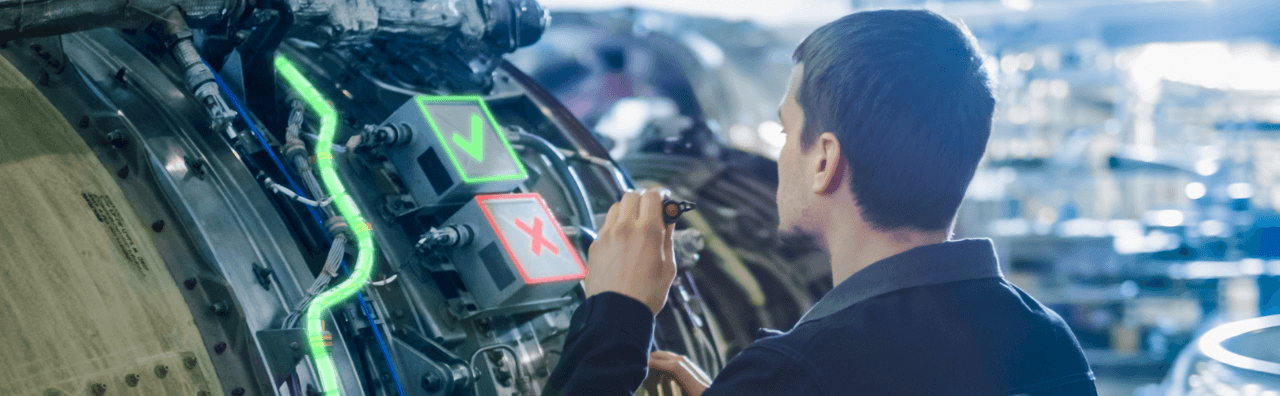

Enter a New Era of Human + Machine Collaboration

As you consider the future of manufacturing and the shift from Industry 4.0 to Industry 5.0, it’s critical that you empower your workforce with digital technologies that help them succeed. Gartner Research predicts that by 2025, up to 80% of all products manufactured, packed, shipped and delivered will still be touched by a person.

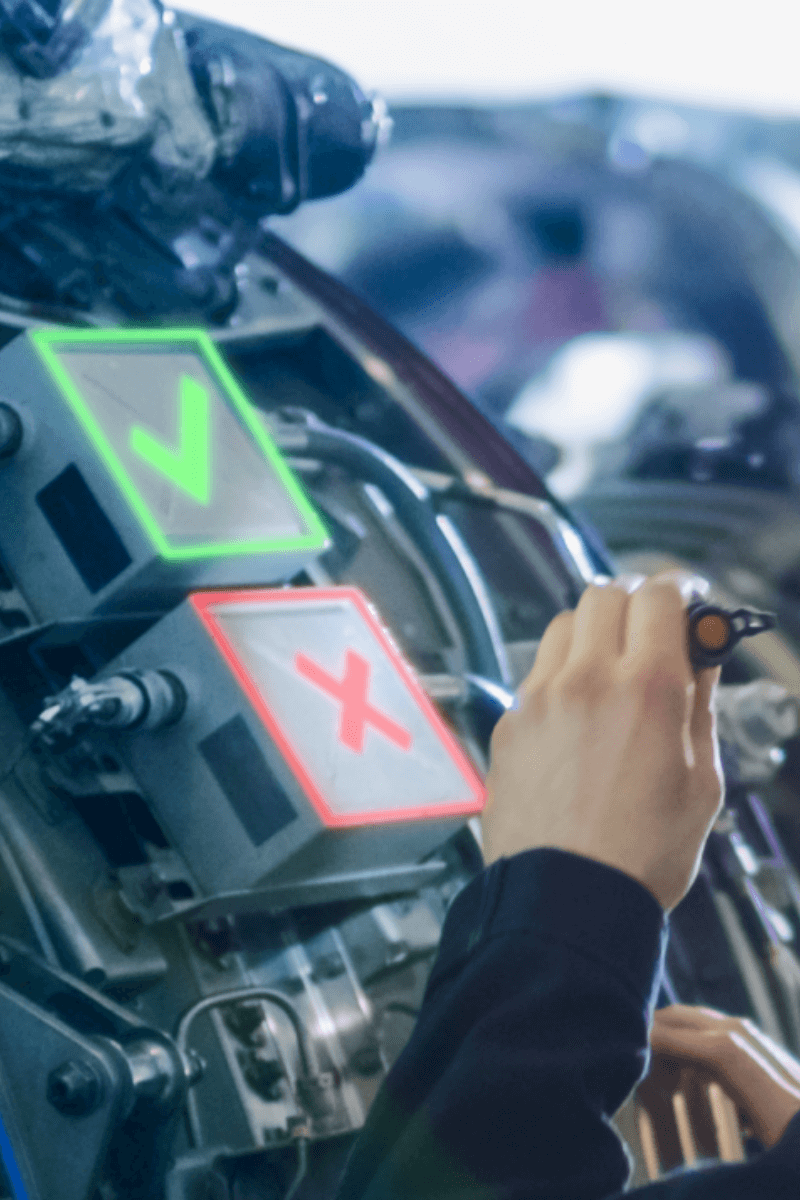

As the premier visual guidance platform globally, LightGuide AR is a powerful addition to your smart manufacturing environment. The LightGuide AR software platform utilizes one or more industrial-grade projectors interfaced to sensors, cameras, input devices, and smart tools to visualize and error-proof the workflow.

Imagine LightGuide in Your Factory of the Future

LightGuide Projected Augmented Reality (AR) Software dramatically improves complex manual processes.

Get StartedDiscover the Industrial AR Software Leading Manufacturers Trust to Power their Factories of the Future

- 90% Improvement in Quality

- 50% Improvement in Throughput

- 30% Improvement in Training Effectiveness

Trending Insights for Manufacturing Excellence

6 Uses of Augmented Reality for Manufacturing In Every Industry

Augmented reality (AR) is changing the way we connect and interact in manufacturing. Discover how AR enhances manufacturing capabilities, making it a perfect tool for Industry 4.0.

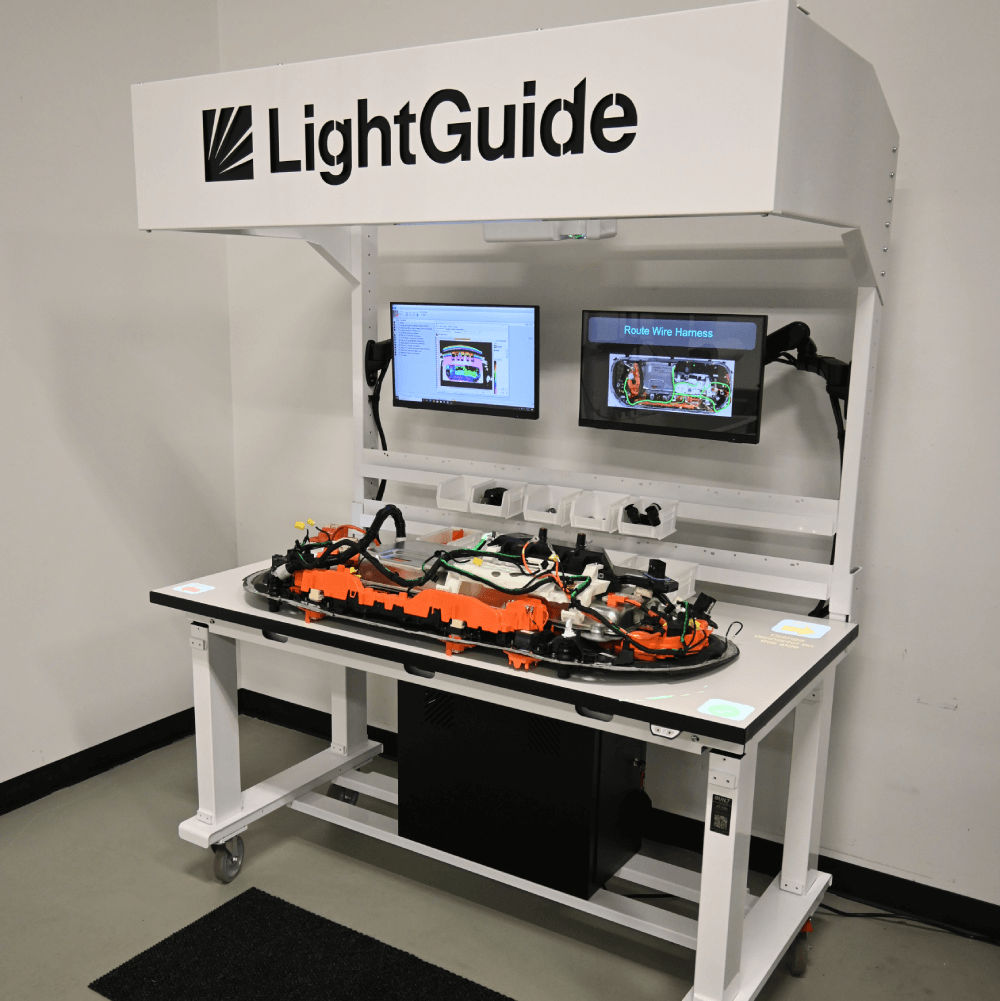

Learn MoreLightGuide smartAR™ Workstation

The all-in-one smartAR Workstation redefines how augmented reality is deployed to the factory floor. As a pre-engineered system, it combines all required hardware and software needed for LightGuide AR visual guidance.

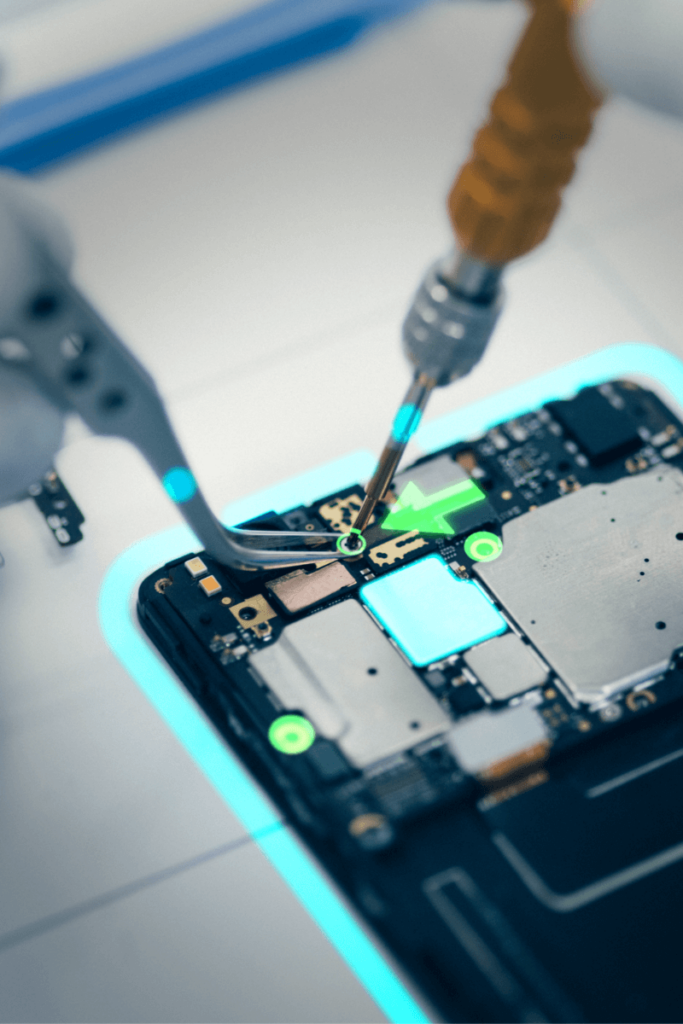

Explore the FeaturesLightGuide smartAR™ Desktop

Run training, assembly, inspection, and repair operations for small form-factor parts and processes, like portable electronics, PCBAs, cell phones, tablets, game controllers, and more. It’s powerful, portable projected AR.

Experience ItAugmented Reality (AR) Applications on the Factory Floor

Not all types of AR are created equal. Use this guide to discover which type of AR is best suited for your ideal use case. Plus, learn how to standardize, streamline, and error-proof complex manual processes.

Download Ebook

LightGuide AR Platform

LightGuide augmented reality uses digital projection technology to overlay a virtual operating “canvas” onto any work surface, simplifying complex manual tasks. By interfacing with existing manufacturing equipment, the system delivers immersive, interactive visual work instructions that comprise a company’s key assembly, inspection, material handling, and training operations.