As manufacturing and service companies prepare to restart their operations in the coming weeks following long shutdowns due to the COVID-19 pandemic crisis, there are several critical elements where Augmented Reality (AR) can enable and assist a safe and efficient restart process.

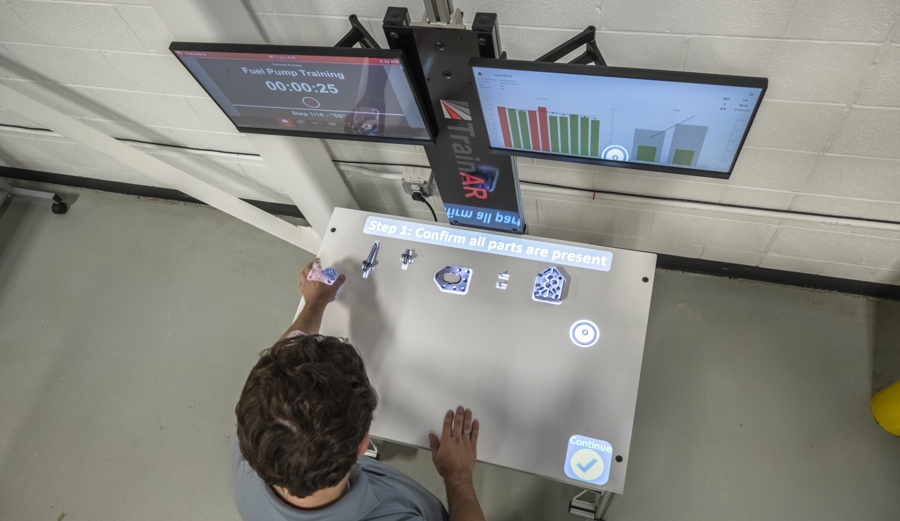

Retraining for the Restart: With the long shutdowns, companies will be faced with retention and recruitment challenges, and as a result will face significant training workload in the coming weeks. In addition, planning for a phased-in return to the workplace generally is indicating a workforce that is ~50% less dense than before the pandemic crisis began. AR has been proven to be highly effective in training employees in new processes or products, as well as remedial training for pre-existing work assignments.

Low-Density Operations: Consistent with the new Social Distancing norms we are practicing in the general public, the workplace will have to be reconfigured to allow for the recommended safe distances, i.e. six feet spacing between workstations. In this new low-density scenario, assembly processes will have to be redesigned and work stations spaced further apart, and team members will have to be able to perform multiple process steps. In this more complex environment, AR again can provide the proper guidance and confirmation that products are built efficiently and at high-quality levels.

New Disinfection Requirements: All companies will need to comply with new stringent regulations for providing a sterile workplace. Studies have demonstrated that relying on checklists and human memory doesn’t ensure critical surfaces are properly sanitized. AR on a wearable platform, combined with spatial recognition, can provide standardized work instructions to ensure compliance and confirmation that these sanitizing processes are performed correctly and completely every time.

New Requirements for PPE and Health Screening: AR can self-guide employees entering the workplace in a standardized Personal Protective Equipment (PPE) and Health Screening process, with auto-confirmation that all required PPE is adorned as well as Health Check screening for fever and other symptoms; a successful screening event can then be associated with the employee’s badge for safe entry into the workplace.

Proper PPE Kitting and Availability: If faced with a lack of proper PPE inventory levels and staging throughout the workplace, operations will be impacted if employees are unable to work without PPE. AR kitting systems can both guide and confirm that the appropriate PPE quantities are properly stocked in the right place and at the right time.

While the “new normal” will present a number of challenges in the workplace, with the right approach and right technology you can effectively and efficiently mitigate the risks. Please let us know what your biggest challenges are, and we can advise you on how to address them with LightGuide Systems for a safer, more productive workplace.