Revolutionizing Material Handling with Augmented Reality

LightGuide SpotGuideAR is a comprehensive augmented reality (AR) system designed specifically for material handling. It utilizes dynamic, programmable spotlight projectors that integrate seamlessly with factory interfaces, providing an innovative and efficient solution for guiding and organizing materials in real-time.

LightGuide’s SpotGuideAR platform is a game-changer in the world of warehouse operations, bringing a new level of efficiency and precision to essential activities. Our innovative use of spotlight projectors provides real-time instructions and guidance, enabling warehouse associates to perform tasks with unmatched accuracy and speed.

Key Applications of SpotGuideAR:

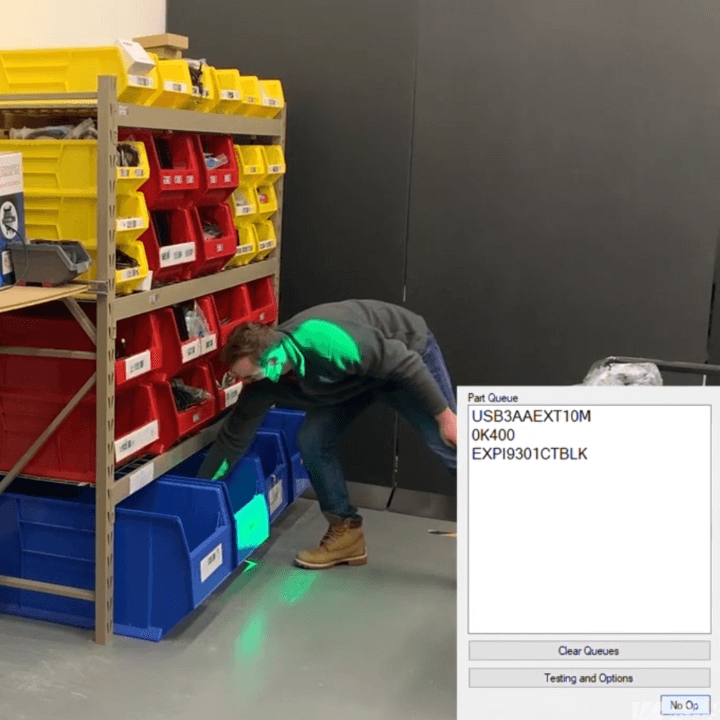

- Seamless Parts Movement: Streamline the movement of parts within warehouses and logistics centers with point A-to-B light guidance, reducing errors and improving workflow.

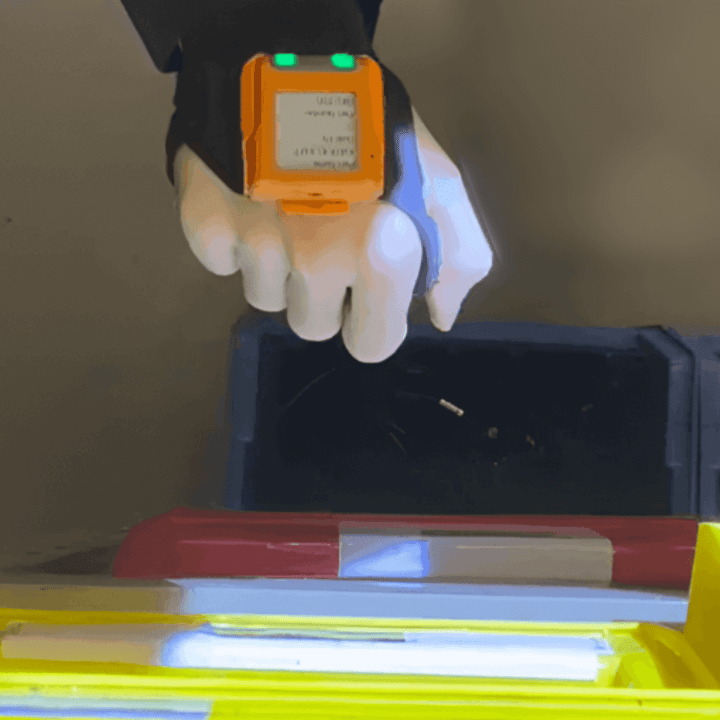

- Improved Pick-and-Place Operations: Elevate material handling operations with accurate pick-and-place guidance, resulting in improved throughput and reduced chances of errors.

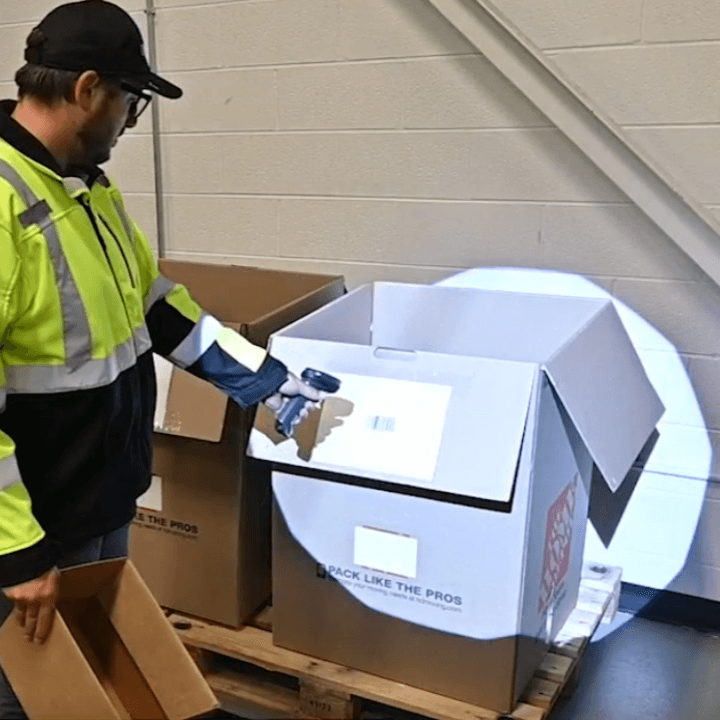

- Efficient Shipping Dock Staging: Optimize the staging process at shipping docks, ensuring that goods are organized and ready for transport with precision.

- Enhanced Walking Routes: Guide warehouse personnel along the most efficient and safe walking routes, minimizing travel time and increasing overall productivity and safety.

Video

Key Features of SpotGuideAR:

- User-Friendly Interface: Designed with simplicity in mind, SpotGuideAR eliminates the need for engineers, allowing production personnel to operate the system with ease.

- Ready Out of the Box: Pre-configured before shipping for immediate use upon arrival.

- Hassle-Free Setup: Plug-and-play hardware ensures a quick and easy installation process.

- Versatile Spotlight Projectors: Available in various sizes to accommodate different workspace needs.

- Scalability: Capable of expanding up to 12 spotlights on a single PC to suit growing operational demands.

- Mounting Flexibility: Offers both standard and flexible mounting options to fit various factory layouts.

- Energy-Efficient: Utilizes low-power spotlight equipment to reduce energy consumption.

- 90%+ Quality Improvement

- 70%+ Training Efficiency

- 50%+ Productivity Increase

LightGuide AR Platform

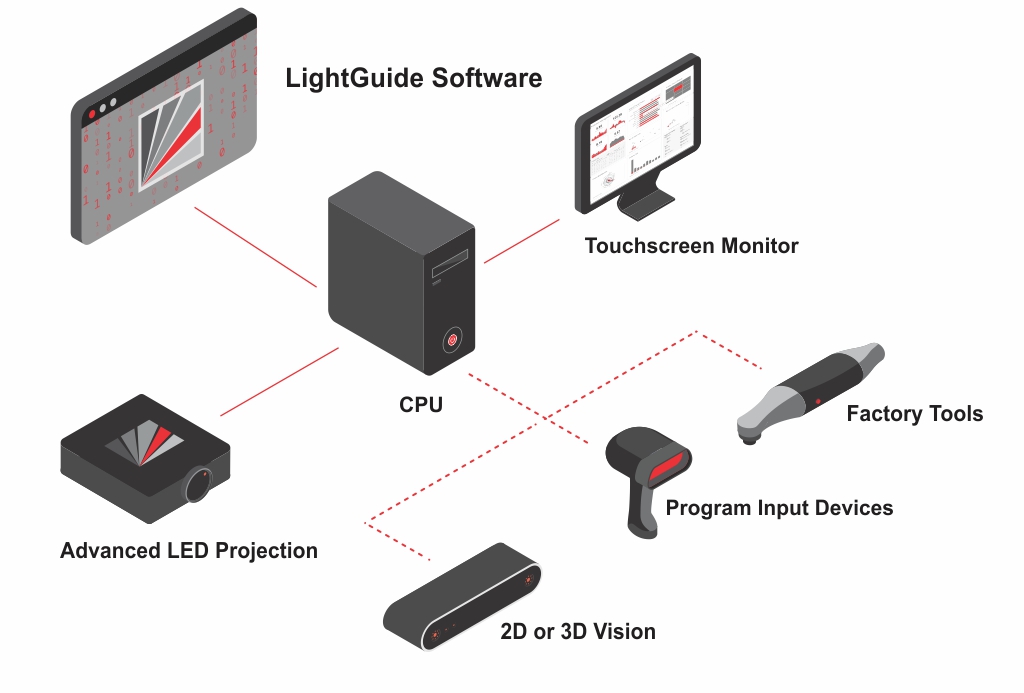

LightGuide augmented reality uses digital projection technology to overlay a virtual operating “canvas” onto any work surface, simplifying complex manual tasks. By interfacing with existing manufacturing and warrehouse software and equipment, the system delivers immersive, interactive visual work instructions that comprise a company’s key assembly, inspection, material handling, and training operations.

Trusted by the World’s Most Innovative Companies

|

|

|

|

|

|

|

|

|

|

|

|

Your Guide to AR Applications on the Factory Floor

Not all types of augmented reality are created equal. Use this guide to discover which type of industrial AR is best suited for your factory application, learn from real-world case studies, and more.

|

|