Trusted by the World’s Leading Electronics Companies

|

|

|

Resolve Common Electronics Manufacturing Challenges with AR Workflows

In an industry grappling with constant innovation and short product lifecycles, where human errors account for many defects, electronics companies are rethinking how they approach assembly, repair, and recycling to achieve higher levels of quality and productivity.

LightGuide’s projected augmented reality (AR) workflow platform fast-tracks the adoption of new processes to dramatically improve quality, safety and productivity.

Unlock the Power of AR Workflows with LightGuide

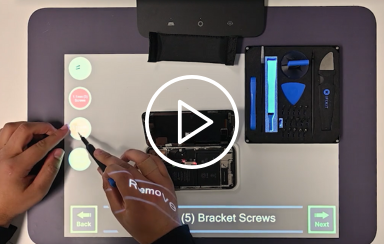

As the premier digital work instruction platform, LightGuide’s projected AR software interfaces with industrial-grade projectors, sensors, and smart tools to guide technicians through each step of the process.

- Standardize repair processes and reduce complexity by transforming instructions into visual workflows that guide technicians in real-time

- Prevent errors and improve bounce rates with integrated sensors and vision cameras that confirm repairs are completed correctly

- Improve traceability and gain insight into valuable repair data, with the ability to track throughput, mean time to repair, and bounce by device type

Video

LightGuide AR Delivers Proven Results

- 90%+ Quality Improvement

- 70%+ Training Efficiency

- 30%+ Productivity Increase

Your Guide to AR Applications on the Factory Floor

Not all types of augmented reality are created equal. Use this guide to discover which type of industrial AR is best suited for your factory application, learn from real-world case studies, and more.

|

|

Leading Manufacturers Have Dramatically Improved Their Processes. So Can You.

5 Electronics Manufacturing Challenges Augmented Reality Solves

Do any of these challenges sound familiar? Learn how leading electronics manufacturers are using projected AR to improve training, eliminate defects, and boost productivity.

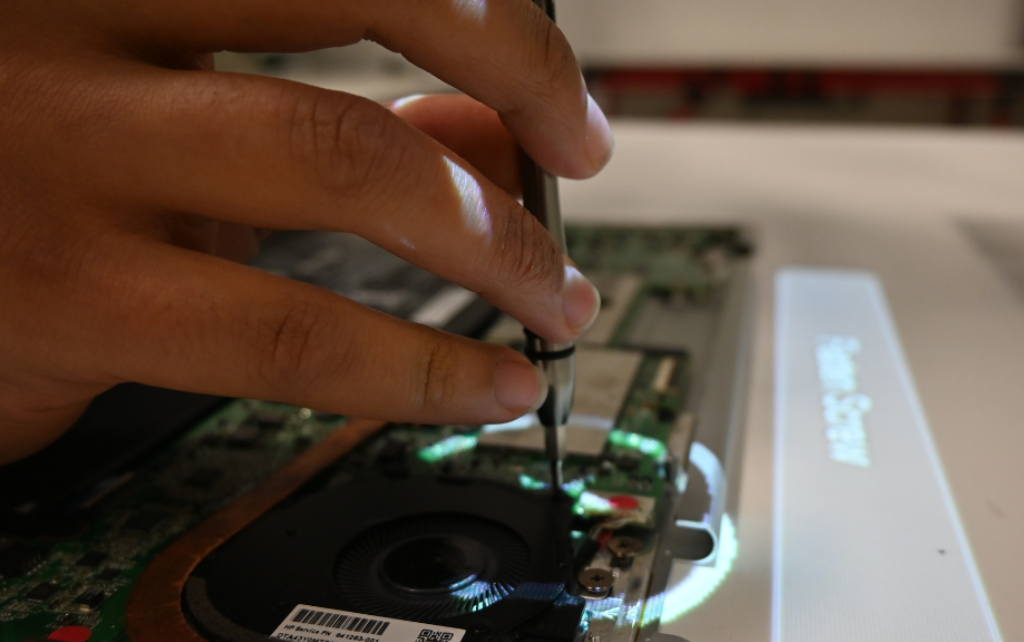

Tech Insurance Company Transforms Electronics Repair Processes with AR

Using projected AR, this company was able to reduce complexity and standardize repair processes by digitizing workflows and providing technicians with precise visual guidance.

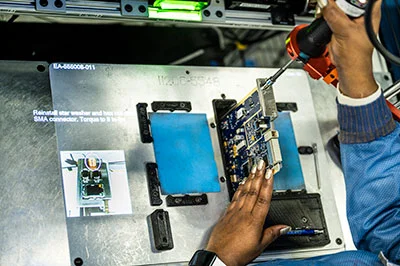

Leading Aerospace & Defense Manufacturer Eliminates Defects with AR Technology

Industry leader L3Harris must ensure its products adhere to the highest standards of quality and reliability. After implementing LightGuide AR work instructions on a line with 17 variants, the company eliminated defects and changeover per variant.

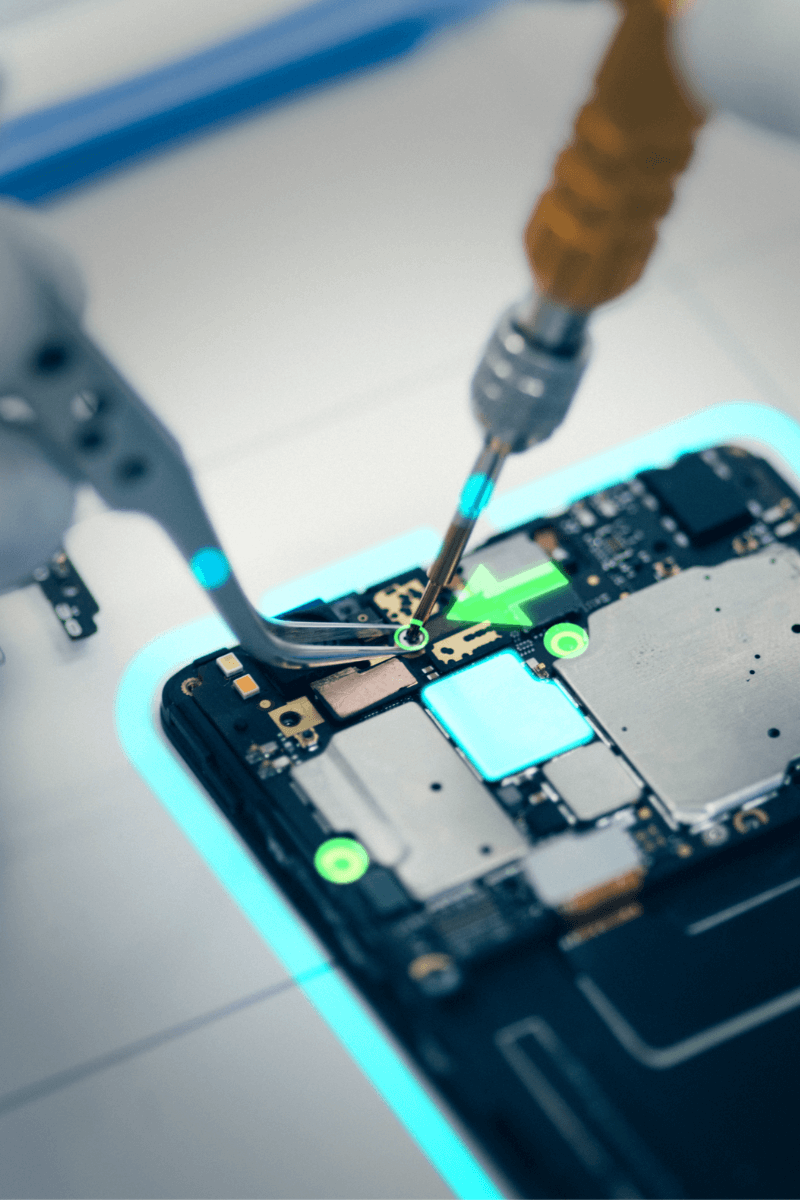

Streamlined Smartphone Disassembly & Repair with Projected AR

With projected AR, repair processes can be standardized to reduce complexity, optimize efficiency, and eliminate errors. This enables technicians (regardless of experience) to achieve consistent, repeatable outcomes when working on different devices.

AR Work Instructions for Efficient & Error-free Electronics Assembly

From circuit boards to laptops to 5G wireless transmitters, we know electronics assembly. AR work instructions visualize and error-proof manual workflows to provide operators with real-time guidance and confirmation for defect prevention.

Integrate Collaborative Robots and AR for Workflow Optimization

See how LightGuide AR work instructions integrate with other digital manufacturing technologies, including cobots, to optimize assembly, repair, and recycling workflows for efficiency, precision, and safety.

Testimonials

"[LightGuide] puts work instructions exactly where you build your product, so you’re reducing time looking at printed instructions by putting the focus exactly where operators’ attention should be."

Let Us Design a Solution for Your Most Challenging Application

Ready to put the power of projected AR to work for you? Our proven platform, deployed across 200+ customers, can deliver predictable results for your most complex manual processes.