Trusted by the World’s Leading Manufacturers

|

|

|

|

|

|

|

|

|

|

|

|

Resolve Manufacturing Challenges with Projected AR Workflows

The future of diversified manufacturing is here. It’s not just about automation, it’s about empowering your workforce with the best possible digital toolset. LightGuide AR is a powerful addition to your Industry 4.0 smart manufacturing systems.

LightGuide’s projected AR work instruction platform standardizes and error-proofs manual workflows for breakthroughs in quality, productivity, and operational agility.

Unlock the Power of AR Workflows with LightGuide

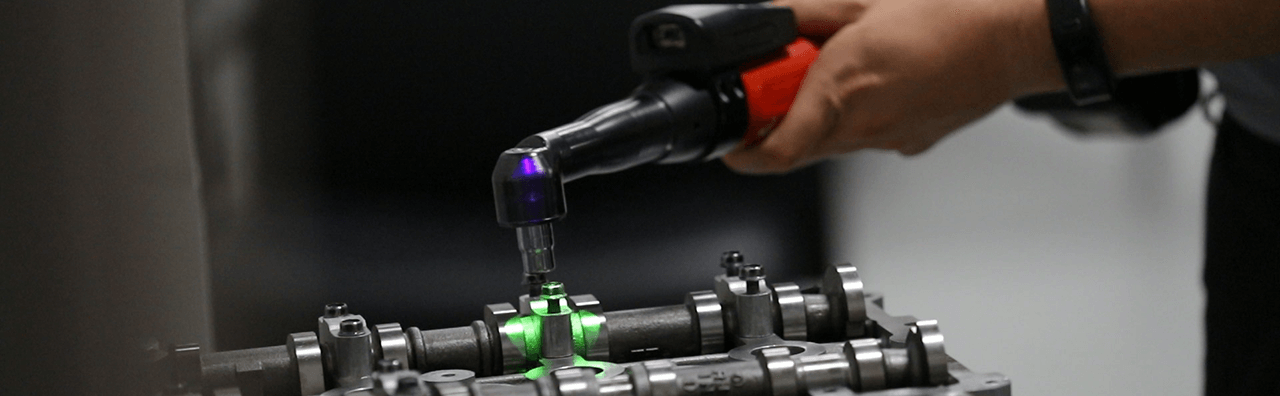

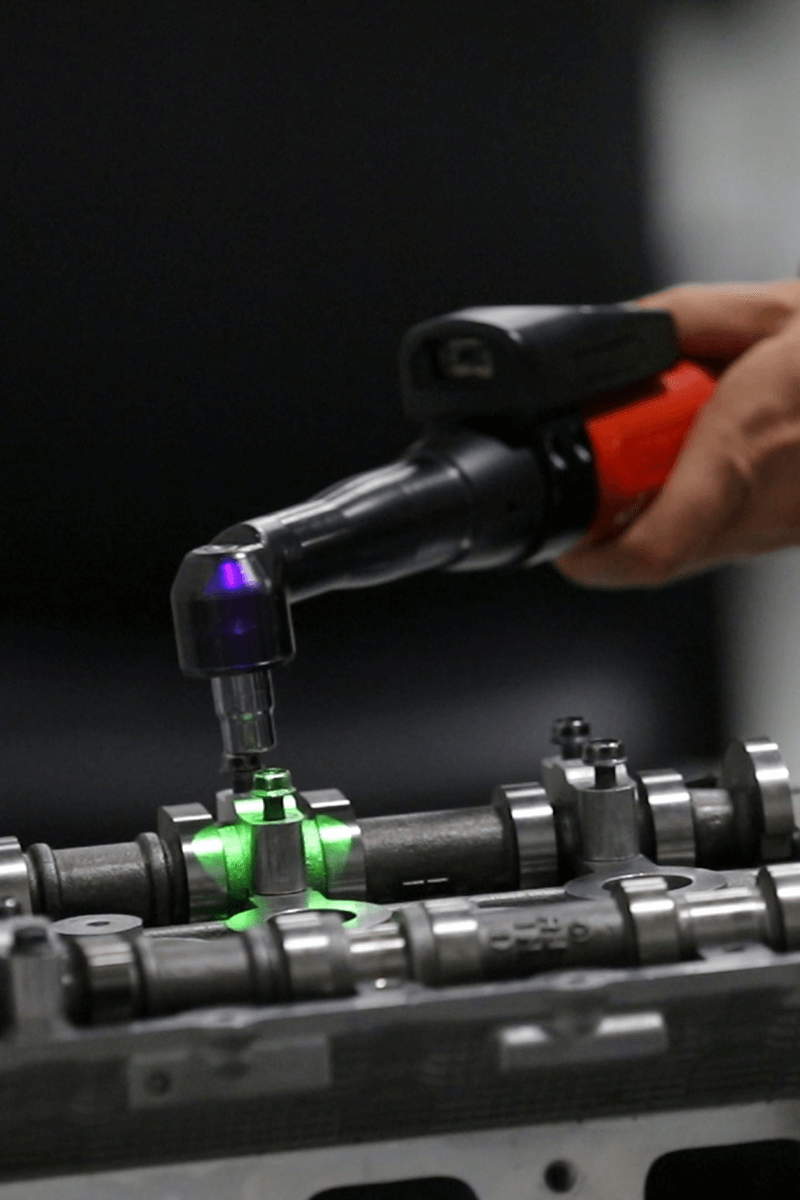

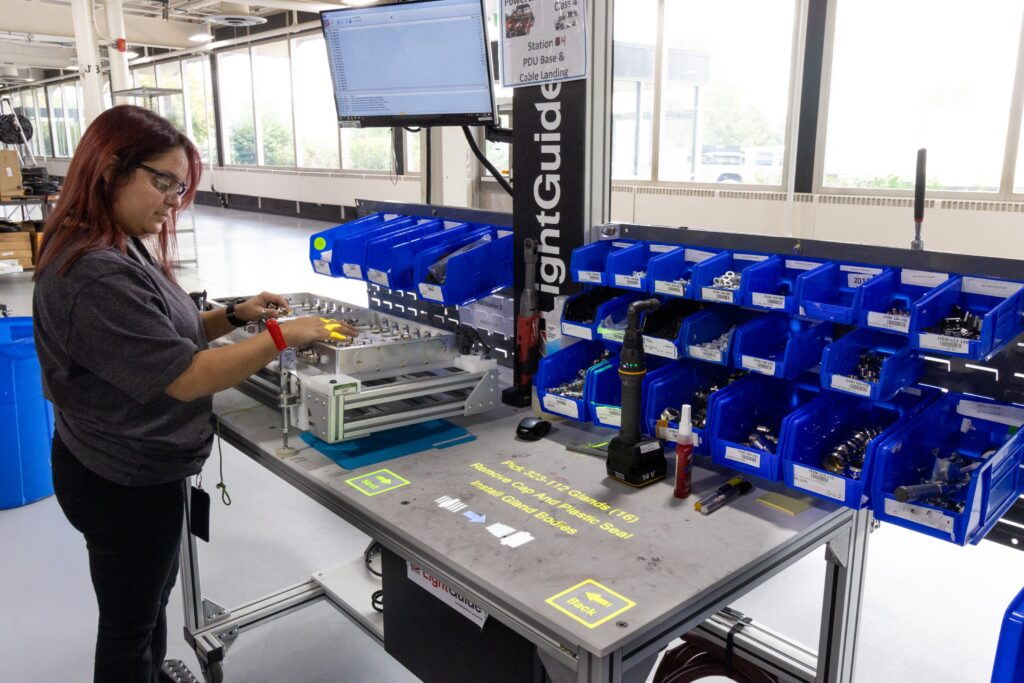

As the premier digital work instruction platform, LightGuide’s projected AR software interfaces with industrial-grade projectors, sensors, and smart tools to guide operators through each step of a company’s key assembly, inspection, material handling, and training operations.

- Prevent errors with interactive AR work instructions projected directly on your operators’ work surface

- Detect errors in real time with 3D sensors and vision cameras that monitor and catch mistakes

- Get real-time data and insights on your operators’ performance and quality

Video

- 90%+ Quality Improvement

- 70%+ Training Efficiency

- 50%+ Productivity Increase

Your Guide to AR Applications on the Factory Floor

Not all types of augmented reality are created equal. Use this guide to discover which type of industrial AR is best suited for your factory application, learn from real-world case studies, and more.

|

|

Featured Resources

6 Uses of Augmented Reality for Manufacturing In Every Industry

Augmented reality (AR) is changing the way we connect and interact in manufacturing. Discover the major benefits of using AR to enhance manufacturing capabilities.

Hydraulic Manufacturer Achieves Zero Defects with AR Work Instruction

Facing complex, high throughput production, this hydraulic manufacturer partnered with LightGuide to eliminate defects, reduce changeover time, and enhance training effectiveness.

Lightning eMotors Adopts AR Work Instructions for Error-free EV Manufacturing

Lightning eMotors, a leader in EV manufacturing and fleet electrification, decreased cycle time by up to 50% and reduced training time by 75% using the LightGuide AR platform.

AR-Guided EV Battery Bay Assembly with Dynamic Tracking

Watch how LightGuide adapts work instructions in real-time to match the movement of AGVs and tables, enhancing worker productivity by ensuring instructions are always in clear view.

Simplify Complex Wire Harness and Cabling Tasks

No more deciphering complex diagrams or misplacing wires! AR work instructions guide operators in real time to error-proof complex wire harness and cabling tasks.

Large Part Kitting and Sequencing Guided by AR

Discover how LightGuide projected AR revolutionizes large-scale part kitting and sequencing processes.

Testimonials

"[LightGuide] puts work instructions exactly where you build your product, so you’re reducing time looking at printed instructions by putting the focus exactly where operators’ attention should be."

Let Us Design a Solution for Your Most Challenging Application

Ready to put the power of projected AR to work for you? Our proven platform, deployed across 200+ customers, can deliver predictable results for your most complex manual processes.