Trusted by the World’s Most Innovative Companies

|

|

|

|

|

|

|

|

|

|

|

|

Elevate Quality, Throughput, and Productivity with LightGuide’s Patented Industrial Augmented Intelligence Platform

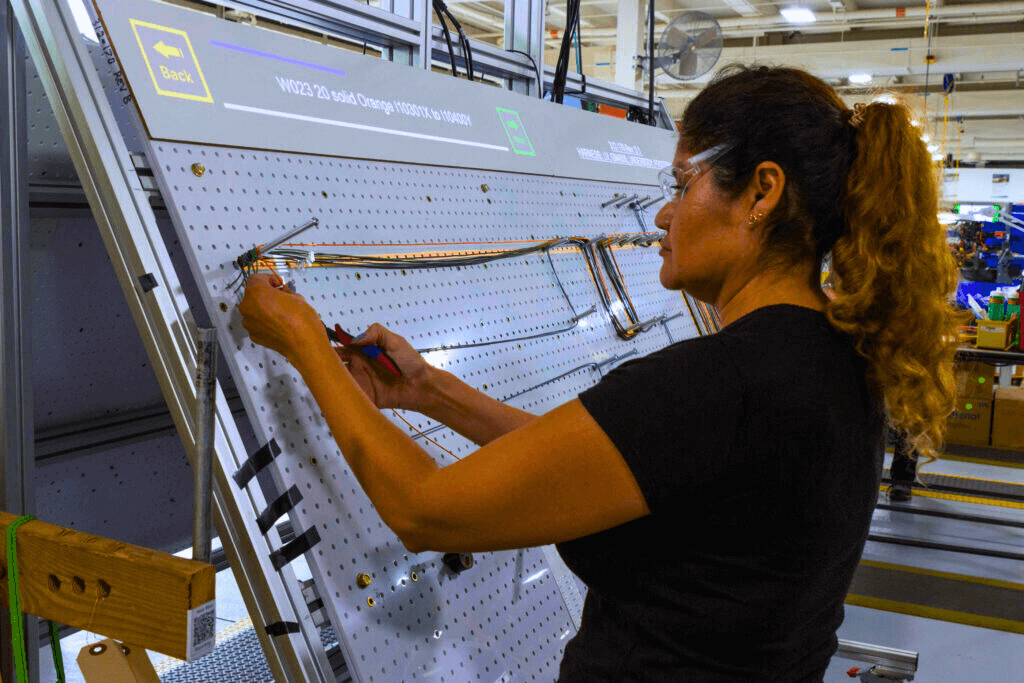

LightGuide seamlessly combines augmented reality (AR) visualization and AI-powered insights to empower frontline teams to perform flawlessly. LightGuide transforms manual processes by projecting digital step-by-step AR work instructions onto an employee’s work surface, standardizing and error-proofing the work. Coupled with AI-driven vision systems and 3D sensors, it proactively prevents and detects errors in real time while capturing data and insights on your operator’s performance and quality.

See our Augmented Intelligence Platform in Action

LightGuide combines AR-powered visualization and AI-powered insights to help businesses overcome their most complex manufacturing and operational challenges by automating complex manual processes.

AI-Driven Precision & Productivity

LightGuide combines AI-powered vision, analytics, and adaptive workflows to enhance quality, efficiency, and real-time decision-making. From automated error detection to intelligent AR guidance, our platform seamlessly integrates with industry-leading AI and cloud solutions to optimize every step of your operation.

Explore our AI Capabilities

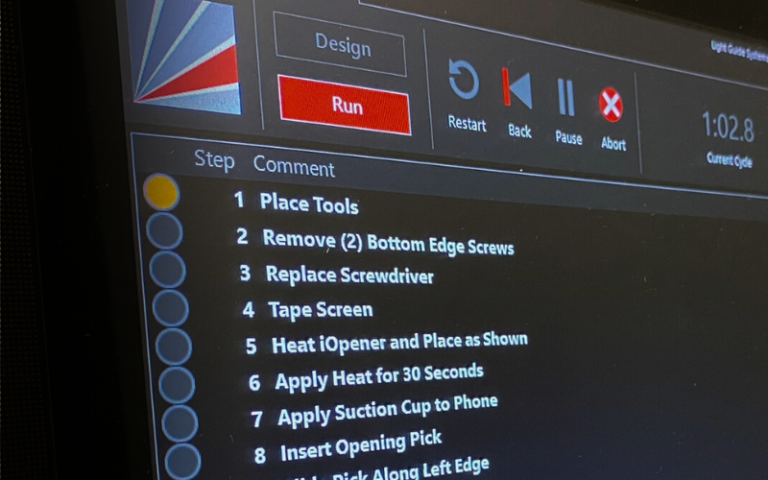

Zero Defect Manufacturing Made Simple

Easily configured, customized, and programmed by your team, LightGuide digitizes complex frontline processes and replaces paper or monitor-based work instructions with projected AR work instructions. It connects seamlessly with your existing factory systems using pre-built digital connectors to hundreds of different MES, PLC, torque tools, cameras, and sensors.

LightGuide Digital Work Instructions: Proven Results

- 90%+ Quality Improvement

- 70%+ Training Efficiency

- 50%+ Productivity Increase

AR Work Instructions for Every Application

From small form factor training to complex, multi-station workcell assembly, there is a LightGuide digital work instruction solution for virtually any application.

LightGuide smartAR™ Desktop

The smartAR Desktop is an all-in-one system for AR work instructions, training and more.

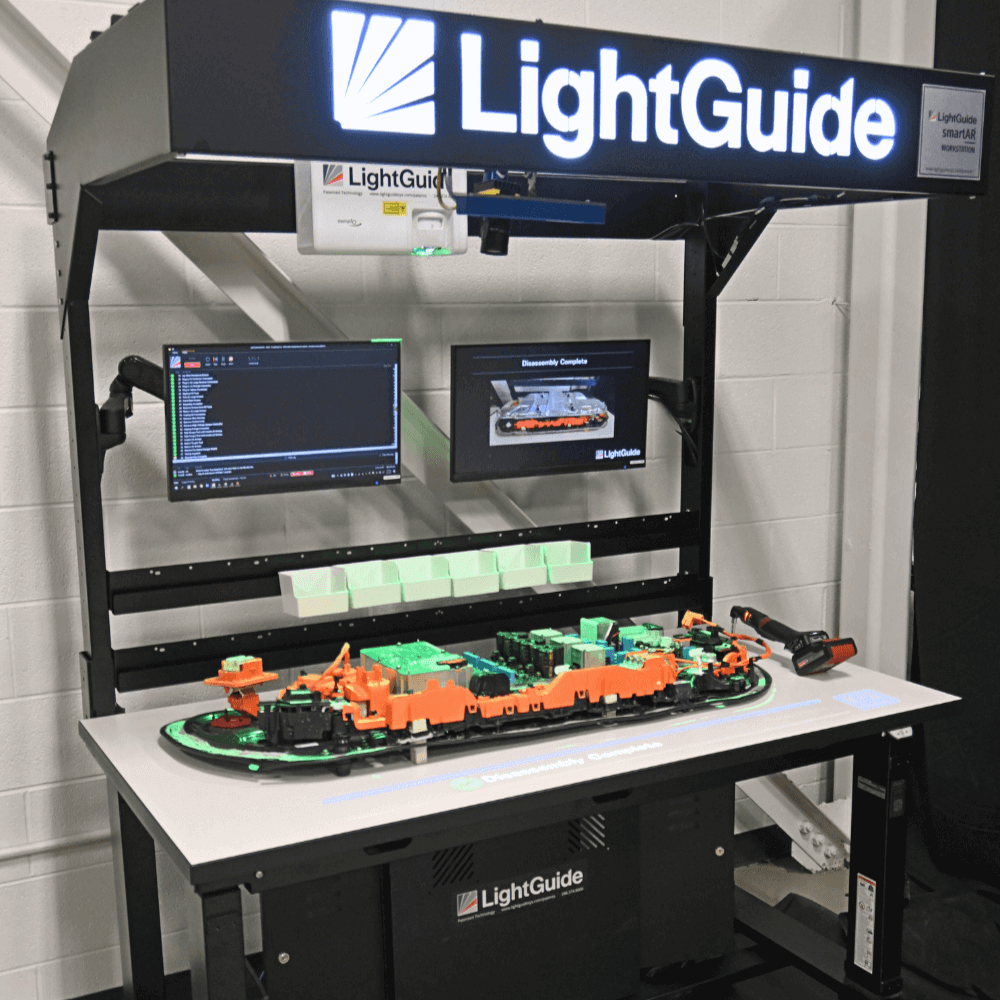

LightGuide smartAR™ Workstation

The smartAR Workstation is an industrial-grade AR system for error-free assembly, inspection and training.

LightGuide smartAR™ Workcell

The smartAR Workcell is a scalable platform supporting the largest and most complex manual industrial applications.

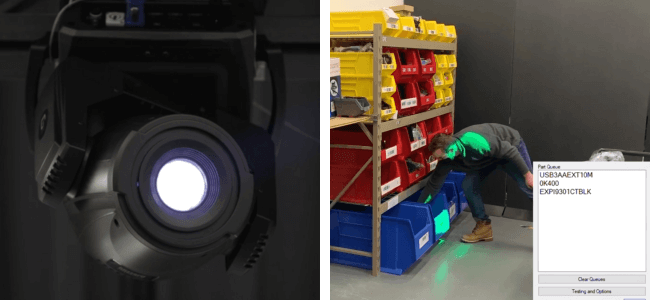

LightGuide SpotGuideAR™ Augmented Reality Warehouse System

LightGuide SpotGuideAR is a comprehensive augmented reality (AR) system designed specifically for material handling. It utilizes dynamic, programmable spotlight projectors that integrate seamlessly with factory interfaces and warehouse management systems.

Learn More

Our Global Network of Enterprise Technology Partners

|

|

|

|

|

|

LightGuide Joins the Siemens Alliance Partner Network | Learn More »

|

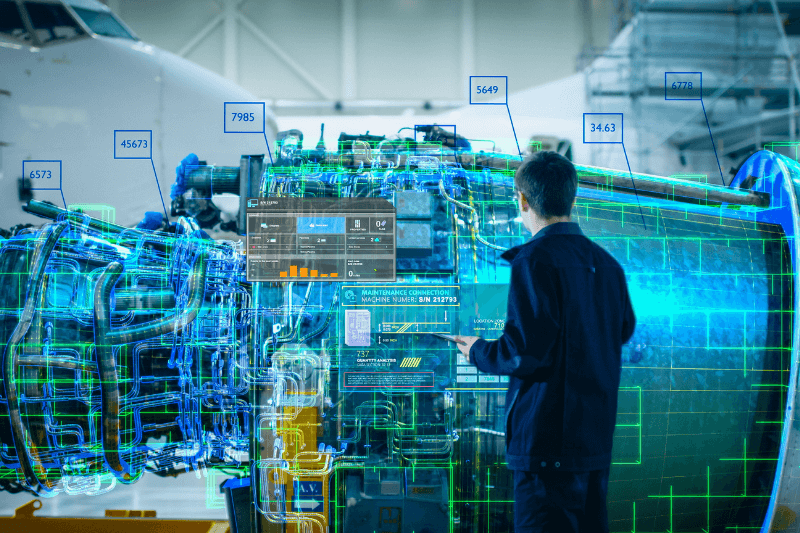

Discover How AR is Reshaping Industrial Processes

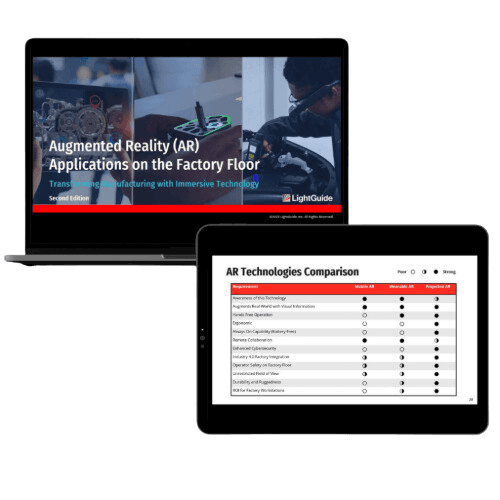

Your Guide to AR Applications on the Factory Floor

Not all types of augmented reality are created equal. Use this guide to discover which type of industrial AR is best suited for your factory application, learn from real-world case studies, and more.

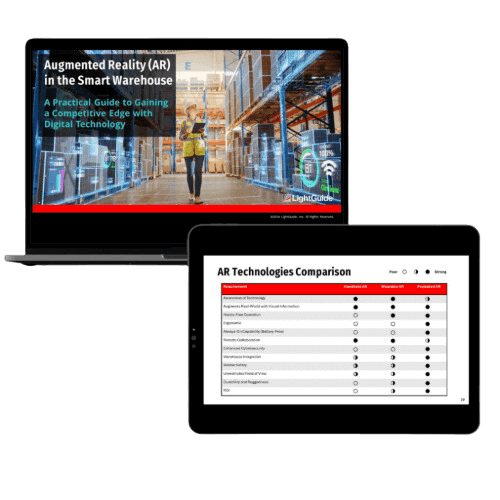

Your Guide to AR Applications in Warehousing & Logistics

Use AR technology to bring “the warehouse of the future” into the present. Explore real-world use cases and more when you download our guide to Augmented Reality in the Smart Warehouse.

Featured Customer Case Studies

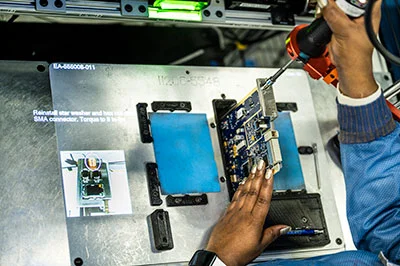

Aerospace & Defense Manufacturer Eliminates Defects with AR

L3Harris relies on the highest standards of quality and reliability. By implementing LightGuide AR work instructions on a complex line with 17 product variants, the company eliminated both defects and changeover time per variant.

Tech Insurance Company Transforms Electronics Repair Processes with AR

Using projected AR, this company was able to reduce complexity and standardize repair processes by digitizing workflows and providing technicians with precise visual guidance.

EV Manufacturer Adopts AR Work Instructions

Lightning eMotors, a leader in EV manufacturing and fleet electrification, decreased cycle time by up to 50% and reduced training time by 75% using LightGuide AR work instructions.

What our Customers are Saying

Testimonials

"[LightGuide] reduces the reliance on operator memory – also known as “cognitive ergonomics” – effectively turning a complex process with multiple steps into a series of simple processes with single steps."

Discover More Industrial Augmented Reality Resources

Digital Work Instructions Explained: The Ultimate Guide

AR-powered digital work instructions are transforming manufacturing by replacing outdated paper manuals with interactive, real-time guidance.

How AR is Transforming Warehousing and Intralogistics

Discover how augmented reality is revolutionizing the warehousing industry by empowering workers to reduce errors and improve productivity.

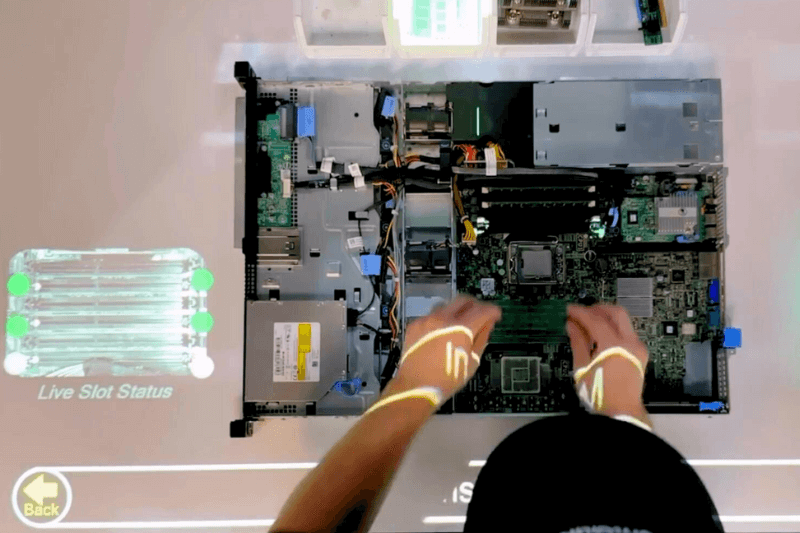

How AR is Revolutionizing Data Center Operations

Discover how augmented reality work instructions are eliminating errors in server assembly, installation, and maintenance while boosting technician productivity.

Ready to Put the Power of AR Work Instructions to Work for You?

Connect with our team to see how LightGuide digital work instructions can transform your operations.