LightGuide Industrial AR WorkCell Deployment

LightGuide’s AR platform improves quality, productivity, and efficiency in your industrial work cells with step-by-step digital instructions overlayed on the real world.

Your workforce will avoid errors, reduce rework, and improve performance on assembly, inspection, quality assurance, and testing applications. LightGuide software connects to and communicates with any MES, PLC, or SCADA environment, ensuring the data flows seamlessly across the factory network with no latency.

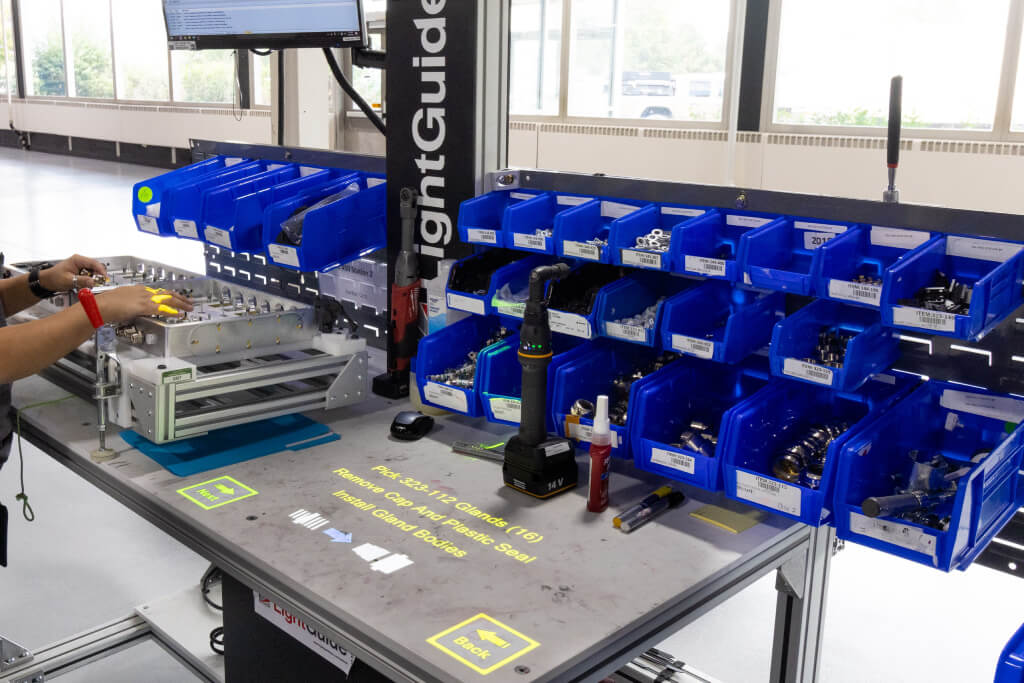

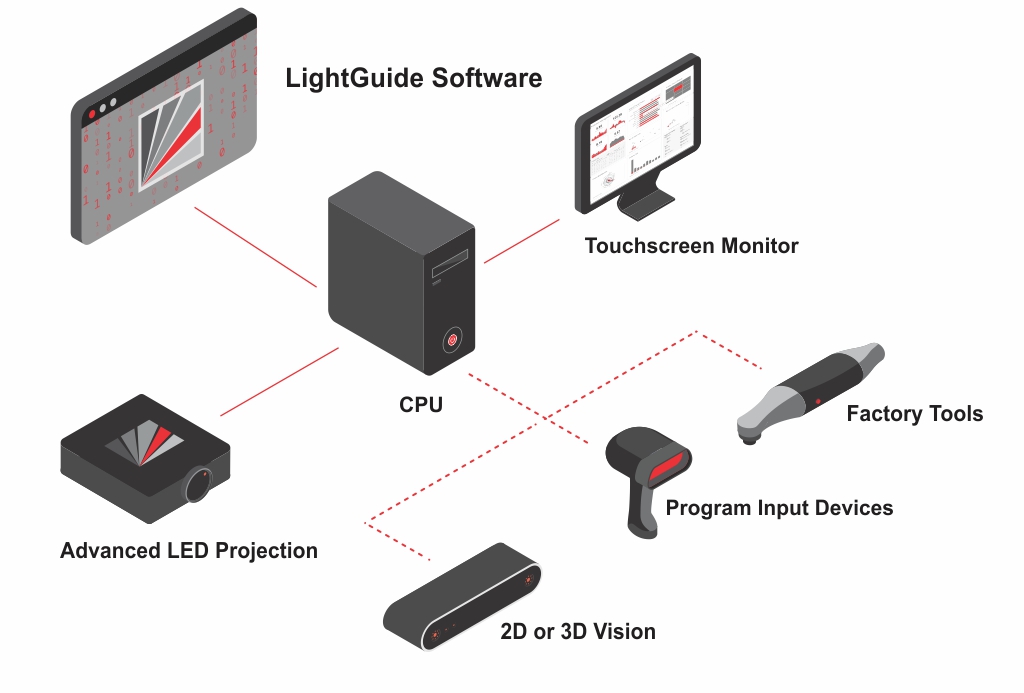

The smartAR Workcell can be designed and deployed to your exact factory specifications with powerful features including:

- High-lumen industrial projectors

- High-resolution 3D cameras

- Machine vision cameras from a variety of manufacturers

- Smart factory tools

- Touchscreen monitors

LightGuide Projected AR systems offer a number of advantages over other forms of AR for industrial workcell applications, including:

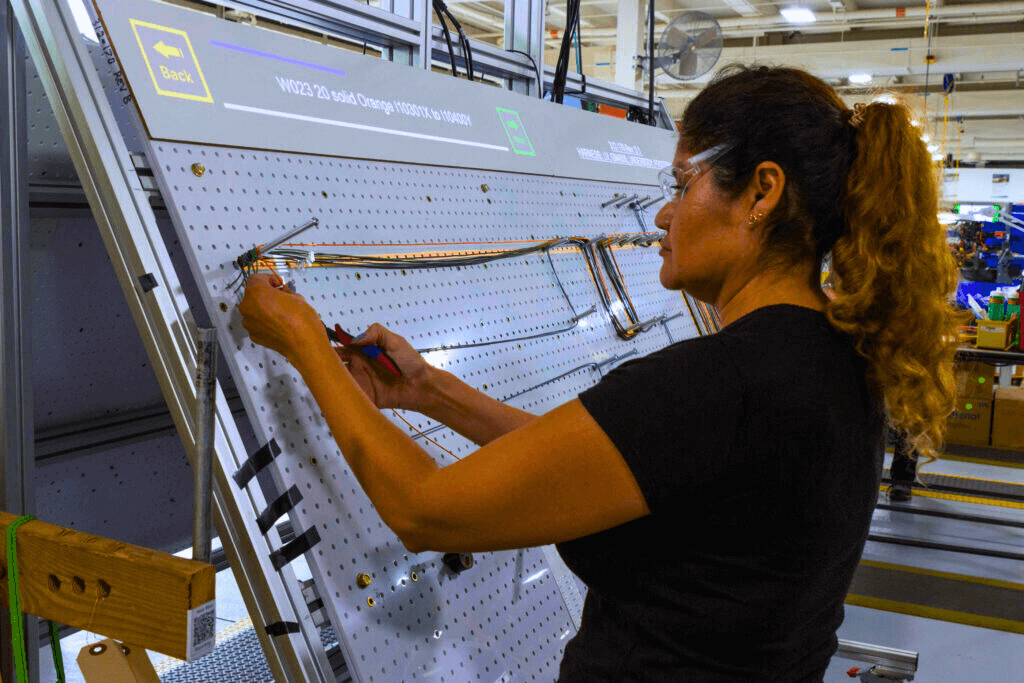

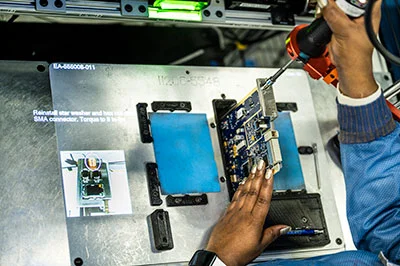

- Hands-free use

- Multi-user capability

- Work instructions appear directly on the work surface

- Line-powered and battery-free

LightGuide AR Platform

LightGuide augmented reality uses digital projection technology to overlay a virtual operating “canvas” onto any work surface, simplifying complex manual tasks. By interfacing with existing manufacturing equipment, the system delivers immersive, interactive visual work instructions that comprise a company’s key assembly, inspection, material handling, and training operations.

- 90%+ Quality Improvement

- 70%+ Training Efficiency

- 50%+ Productivity Increase

smartAR Workcells: The Standard for Industry Leaders

Lightning eMotors Adopts AR Work Instructions for Error-free EV Manufacturing

Lightning eMotors, a leader in EV manufacturing and fleet electrification, decreased cycle time by up to 50% and reduced training time by 75% using the LightGuide AR platform.

Leading Aerospace & Defense Manufacturer Eliminates Defects with AR Technology

Industry leader L3Harris must ensure its products adhere to the highest standards of quality and reliability. After implementing the LightGuide projected AR platform on a line with 17 variants, the company eliminated defects and changeover per variant.

Hydraulic Manufacturer Achieves Zero Defects with AR Work Instructions

Using the LightGuide AR platform, this global manufacturer reduced 769 defective parts per million down to ZERO. In addition to improvements in quality, the organization also realized improvements in changeover time and training effectiveness.

Your Guide to AR Applications on the Factory Floor

Not all types of augmented reality are created equal. Use this guide to discover which type of industrial AR is best suited for your factory application, learn from real-world case studies, and more.

|

|