Trusted by the World’s Leading Aerospace and Defense Companies

|

|

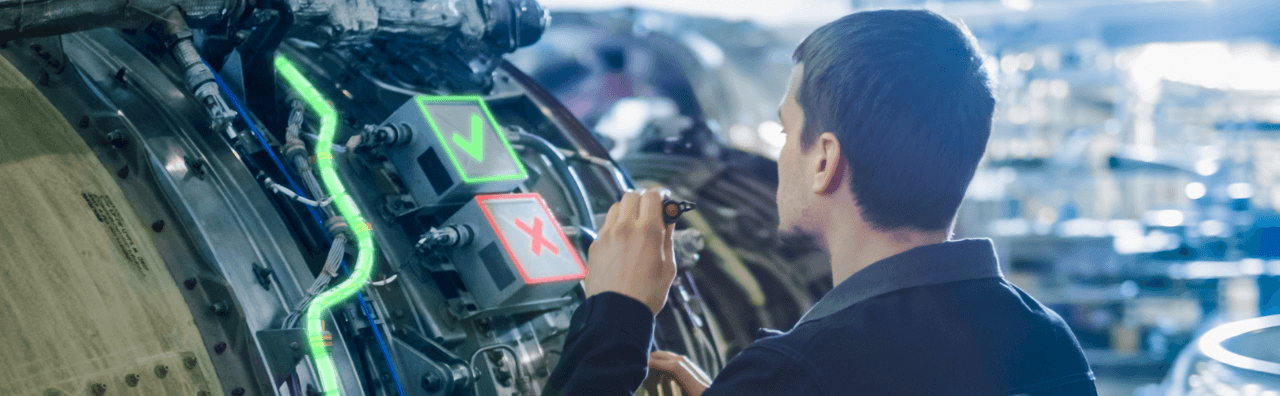

Resolve Manufacturing Challenges with Projected Augmented Reality Work Instructions

Aerospace and defense manufacturing is evolving. Products are becoming more complex, the skills gap is getting wider, and manufacturers are challenged with increasing production to meet growing demand for highly sophisticated aircraft and tactical equipment.

LightGuide’s projected augmented reality (AR) work instruction platform standardizes and error-proofs manual workflows for breakthroughs in quality, productivity, and operational agility.

Explore the Power of LightGuide AR Work Instructions

As the premier digital work instruction platform, LightGuide’s projected AR software interfaces with industrial-grade projectors, sensors, and smart tools to guide operators through each step of a company’s key assembly, inspection, material handling, and training operations.

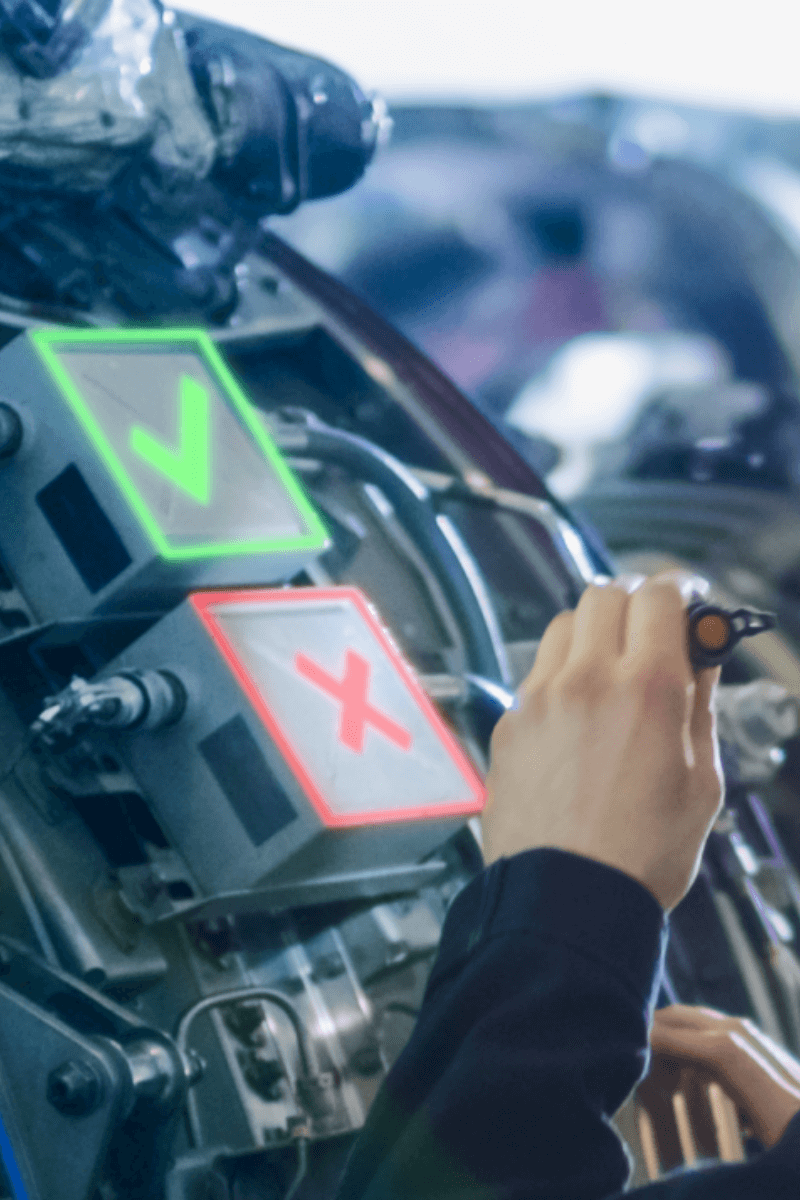

- Prevent errors with interactive AR work instructions projected directly on your operators’ work surface

- Detect errors in real time with 3D sensors and vision cameras that monitor and catch mistakes

- Get real-time data and insights on your operators’ performance and quality

Video

- >90% Improve Quality

- >50% Increase Throughput

- >30% Accelerate Training

Your Guide to AR Applications on the Factory Floor

Not all types of augmented reality are created equal. Use this guide to discover which type of industrial AR is best suited for your factory application, learn from real-world case studies, and more.

|

|

Featured Resources

How to Adopt Augmented Reality for Quality Control in Aerospace Manufacturing

Learn how leading aerospace and defense manufacturers like L3Harris are using projected AR to standardize complex manual assembly processes, eliminate defects and achieve higher quality.

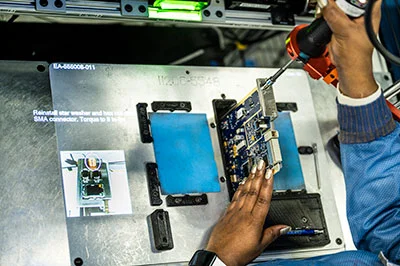

Leading Aerospace & Defense Manufacturer Eliminates Defects with Augmented Reality

Industry leader L3Harris must ensure its products adhere to the highest standards of quality and reliability. After implementing the LightGuide projected AR platform on a line with 17 variants, the company eliminated defects and changeover per variant.

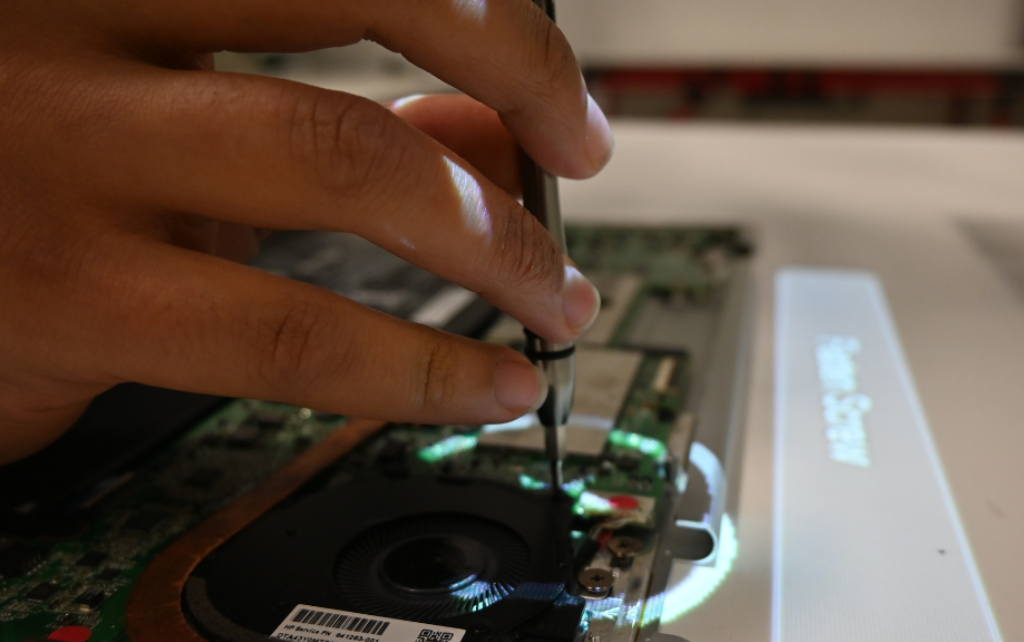

5 Electronics Manufacturing Challenges Augmented Reality Solves

Do any of these challenges sound familiar? Learn how leading electronics manufacturers are using projected AR to improve training, eliminate defects, and boost productivity.

Optimize Wire Harness Routing with Projected AR Work Instructions

See how LightGuide helps manufacturing teams improve precision, reduce errors, and streamline wire harness assembly using real-time, projected AR work instructions.

Error Proof High-Variation Sub-Assemblies

Can your work instructions do this? Watch how LightGuide AR work instructions make it easy for operators to switch between multiple brake hub assembly configurations.

Integrate Collaborative Robots and AR for Workflow Optimization

See how LightGuide AR work instructions integrate with other digital manufacturing technologies, including cobots, to optimize assembly, repair, and recycling workflows for efficiency, precision, and safety.

Testimonials

"[LightGuide] reduces the reliance on operator memory – also known as “cognitive ergonomics” – effectively turning a complex process with multiple steps into a series of simple processes with single steps."

Let Us Design a Solution for Your Most Challenging Application

Ready to put the power of projected AR to work for you? Our proven platform, deployed across 200+ customers, can deliver predictable results for your most complex manual processes.