Augmented Reality Meets Augmented Intelligence

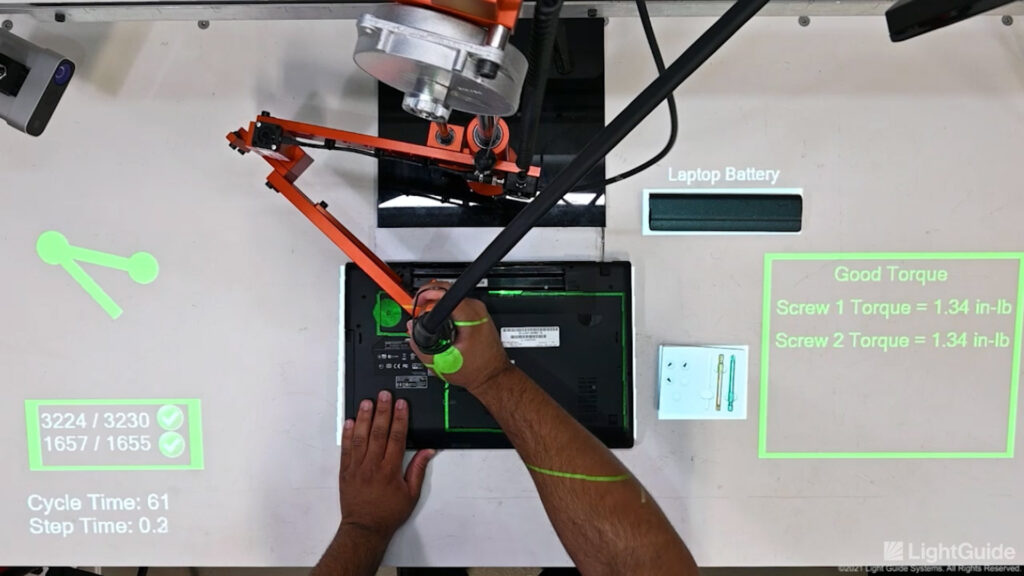

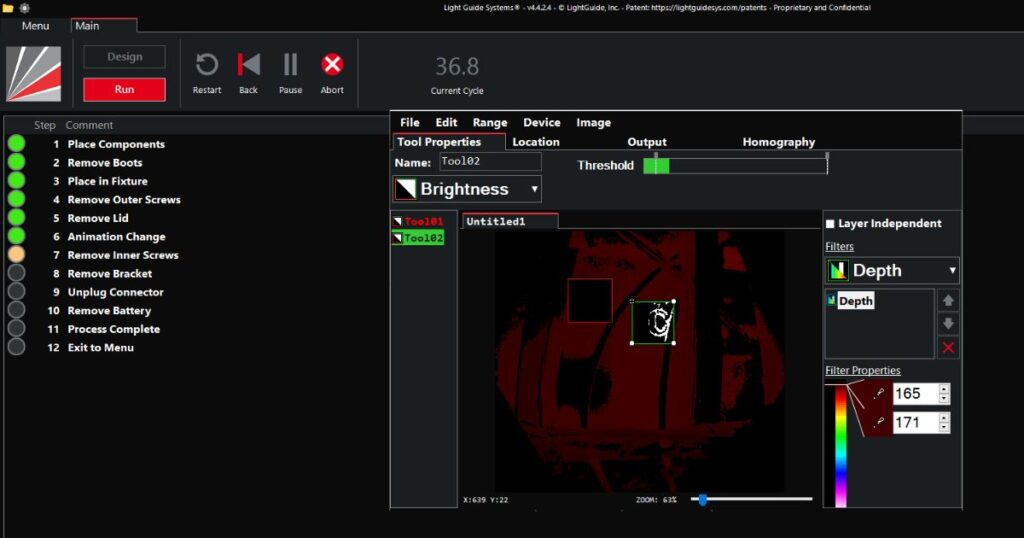

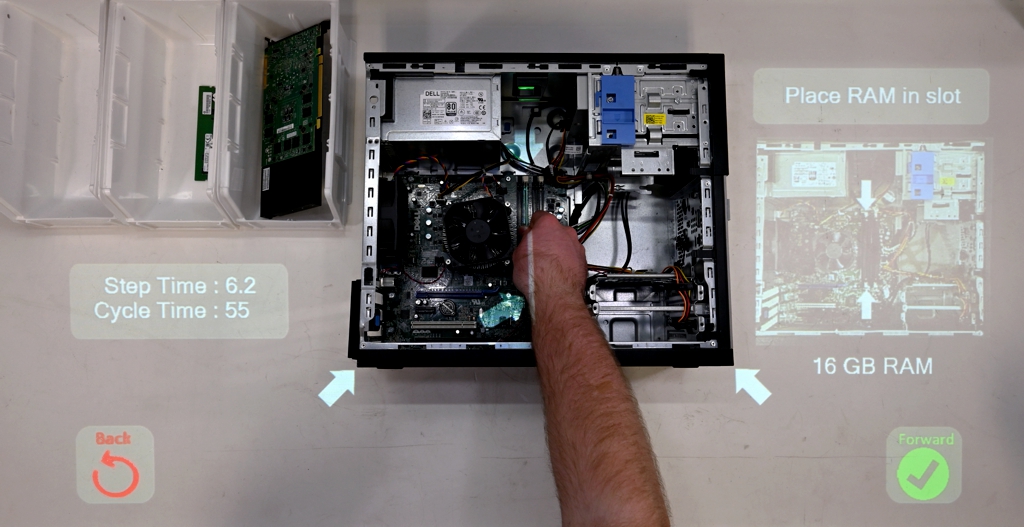

LightGuide’s AI-optimized augmented reality (AR) platform transforms manual processes through intelligent automation and digital worker guidance, making them more efficient, accurate, and compliant. By projecting adaptive, step-by-step digital work instructions onto an employee’s work surface, LightGuide AR standardizes and error-proofs tasks. Integrated with AI-driven vision systems and 3D sensors, it proactively detects and prevents errors in real time, while capturing data and insights on your operator’s performance and quality.

Our Quest for Continuous Improvement and Constant Innovation

Learn about the newest updates and enhancements to the LightGuide software platform.

AI-Driven Precision & Productivity

LightGuide combines AI-powered vision, analytics, and adaptive workflows to enhance quality, efficiency, and real-time decision-making. From automated error detection to intelligent AR guidance, our platform seamlessly integrates with industry-leading AI and cloud solutions to optimize every step of your operation.

Explore our AI Capabilities

LightGuide AR Delivers Proven Results

- 90%+ Quality Improvement

- 70%+ Training Efficiency

- 50%+ Productivity Increase

Transform Work Instructions into an Immersive, Intuitive, Projection AR-guided Workflow.

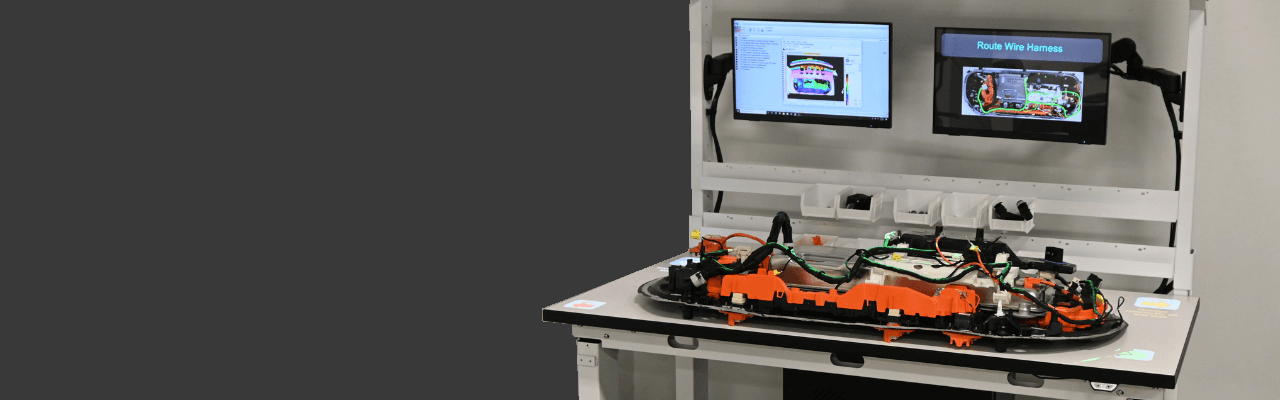

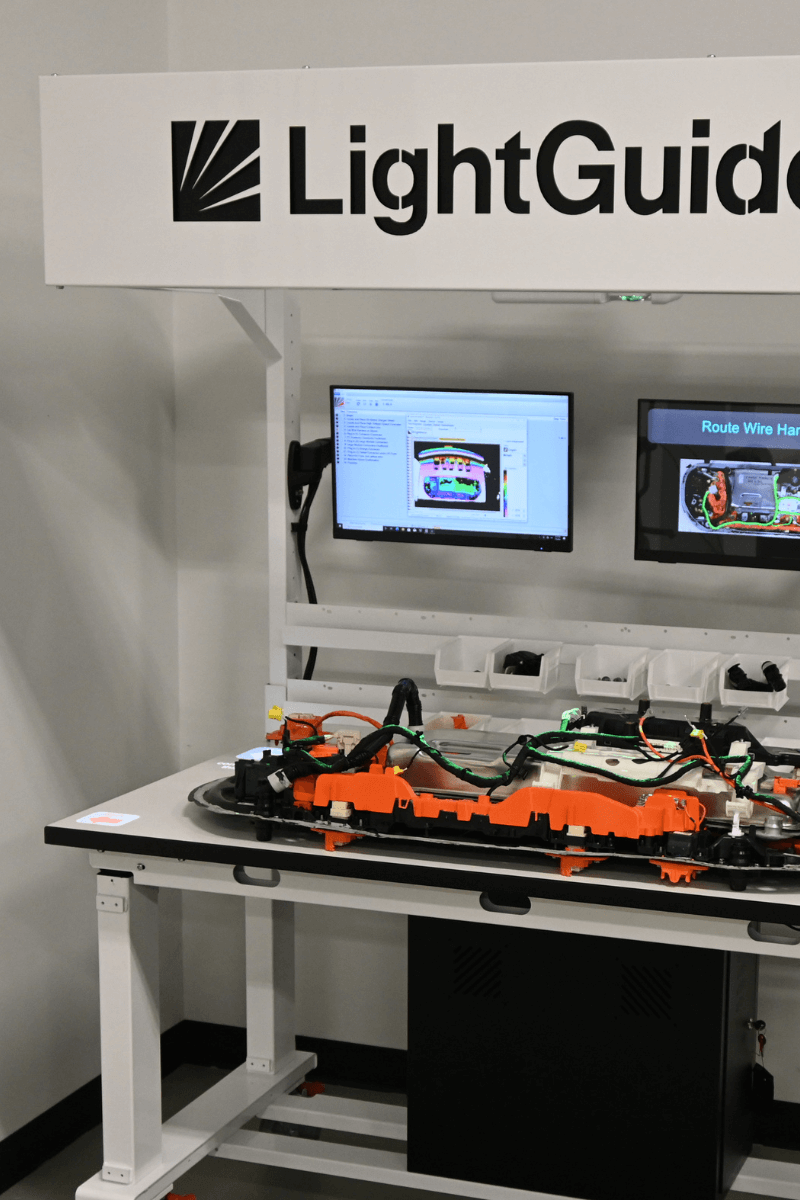

LightGuide Stand-Alone Systems

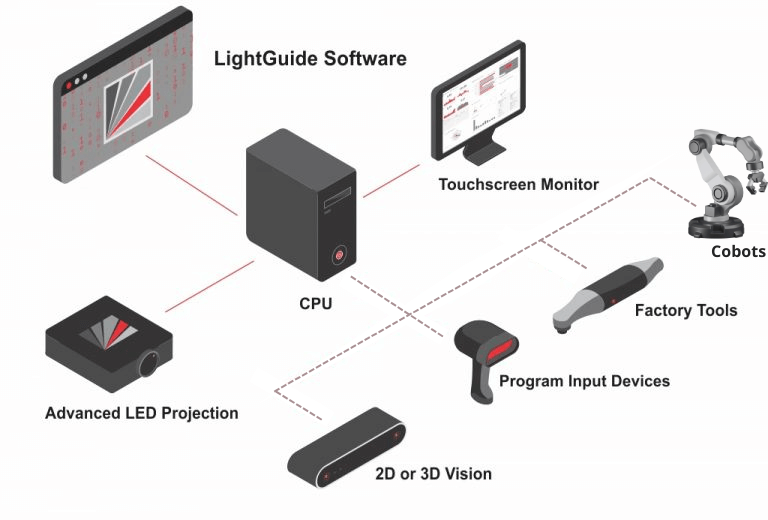

Every LightGuide system is powered by our LightGuide AR software platform, running on a standard Windows 10 PC, driving one or more high lumen, high-resolution industrial-grade projectors, and interfaced to sensors, cameras, input devices, and torque tools to visualize and error-proof the workflow.

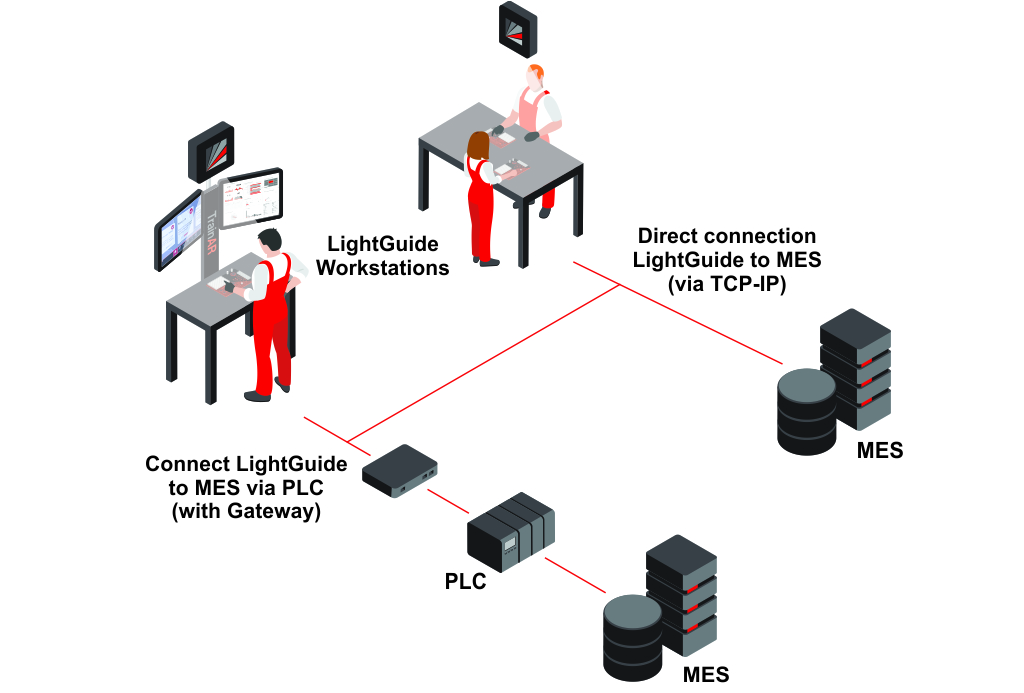

LightGuide Factory Deployment

Upgrade your existing work cells with LightGuide software, bringing the power of projected AR to your factory. LightGuide workstations can power your core operational processes, from part picking to assembly assistance to test, inspection, and training. We connect to and communicate with any MES, PLC, or SCADA environment, ensuring the data flows seamlessly across the factory network with no latency.

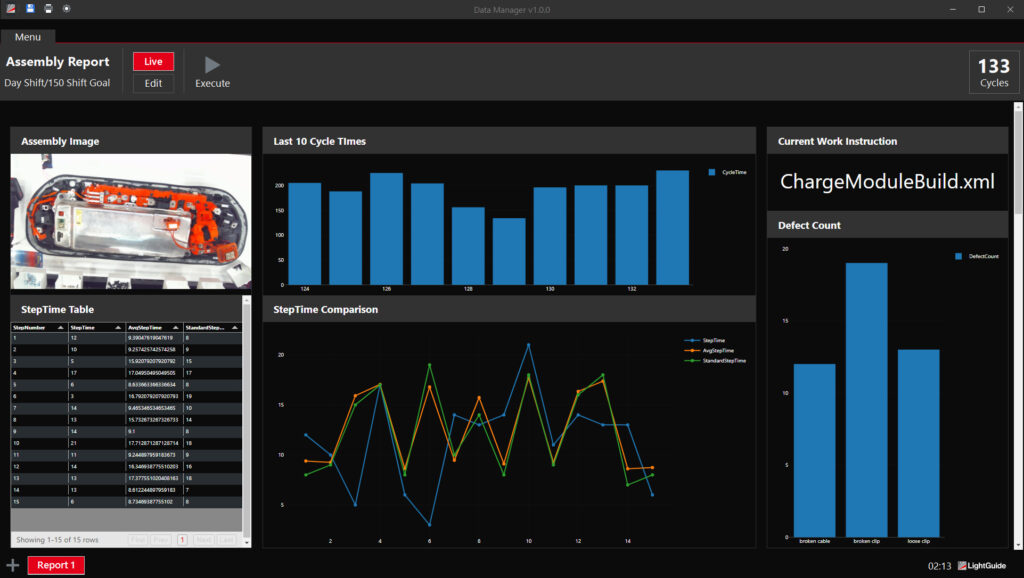

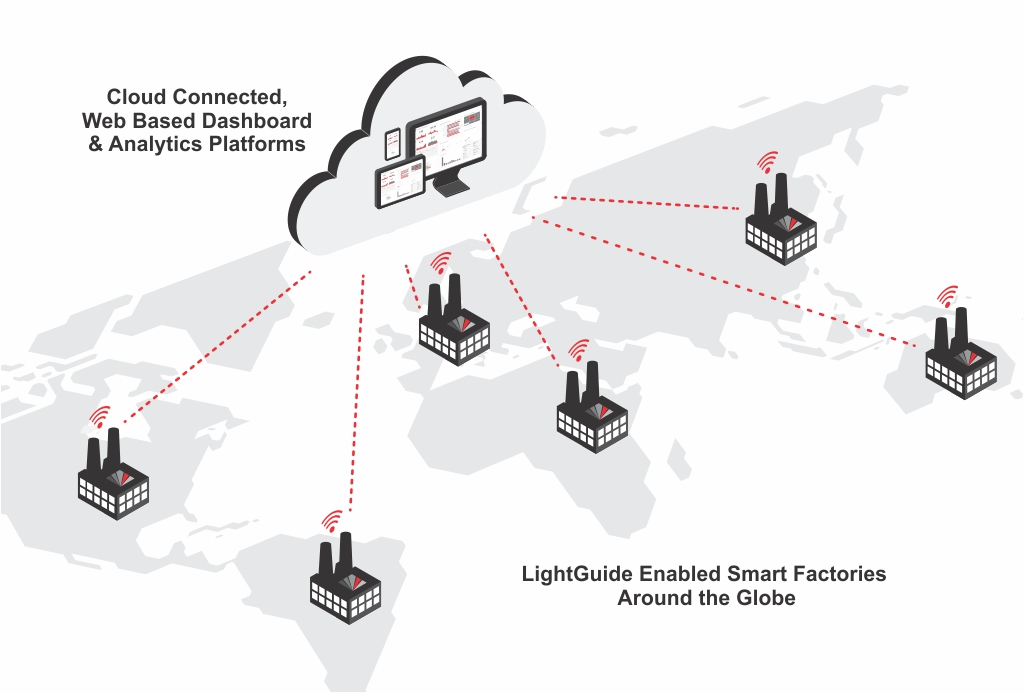

LightGuide Enterprise Connectivity

LightGuide delivers enterprise connectivity for your global manufacturing footprint, with connections to all major web-hosted BI/dashboard environments, enabling full digital traceability and real-time analytics for complex manufacturing processes running anywhere in the world.

Trusted by the World’s Most Innovative Companies

|

|

|

|

|

|

|

|

|

|

|

|