As innovation soars and products become more technologically advanced, operators must keep pace with increasing variation and complexity. Especially for companies delivering equipment to the front lines, products must be reliable, no matter what challenges manufacturers face.

L3Harris Technologies implemented LightGuide AR software to ensure standardization across a variety of complex processes. Following the implementation of LightGuide on a line with 17 variants of one product, visually guided workflows helped consolidate parts, which eliminated changeover per variant and resulted in zero assembly-related defects. Since these results, L3Harris has implemented LightGuide on complex manual lines at multiple locations.

The Challenge

The innate nature of aerospace and defense manufacturing is always to innovate and create the highest-quality products possible. In a fast-moving and increasingly complex world, manufacturers anticipate and rapidly respond to challenges with agile technology — creating a safer world and more secure future. To continue down that path, L3Harris is constantly looking into quality enhancements that reduce the slim margins of error, eliminating all errors if possible.

L3Harris also provides end-to-end solutions, resulting in immense variation. For example, an upcoming line will include more than 30 product variations, which needs intensely optimized standardization to meet its production schedule.

The Solution

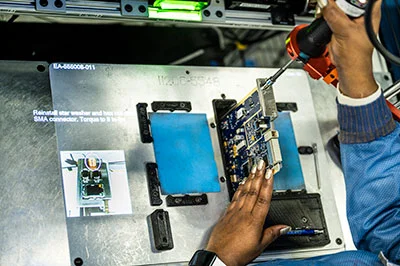

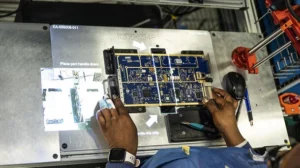

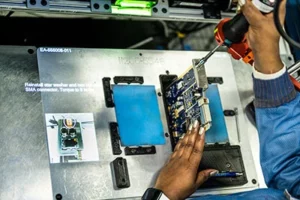

To ensure focus on the task at hand and increase efficiency, L3Harris implemented LightGuide’s patented AR software to streamline and standardize work instructions, decrease the cognitive load on workers, increase quality, and simplify complex manual processes.

LightGuide recognizes the different variations coming down the line through barcode scans. It calls program subroutines to identify what parts the operator needs and then directs them through the assembly process for that product variation.

According to one Engineering Manager at L3Harris, the system uses infrared and 3D sensing to know where an operator’s hand is within an inch in any direction. The cues highlighting what pieces go where allow operators to focus on the task at hand, not where they are in the process; further, the system will notify the operator via visual cues and messaging and stop instruction if they skip a step or reach for the wrong component.

The Results

Using LightGuide’s AR software, L3Harris consolidated parts at a station with 17 variations, eliminating changeover per variant. With a simple barcode scan, variants on the line were immediately identified and work instructions were automatically called to match that process.

L3Harris is now able to make better, data-driven decisions due to the LightGuide system’s ability to collect real-time manual data. “LightGuide has been a great asset for us,” stated the Engineering Manager. “They’ve helped us understand our process better, and even help streamline it by asking the right questions about our order of operations.”

Read the first-hand account of the case study on the L3Harris’ website

Related Content:

How to Adopt Augmented Reality for Quality Control In Aerospace Manufacturing