How Augmented Reality and Machine Vision Ensure Accuracy in Rack Server Assembly

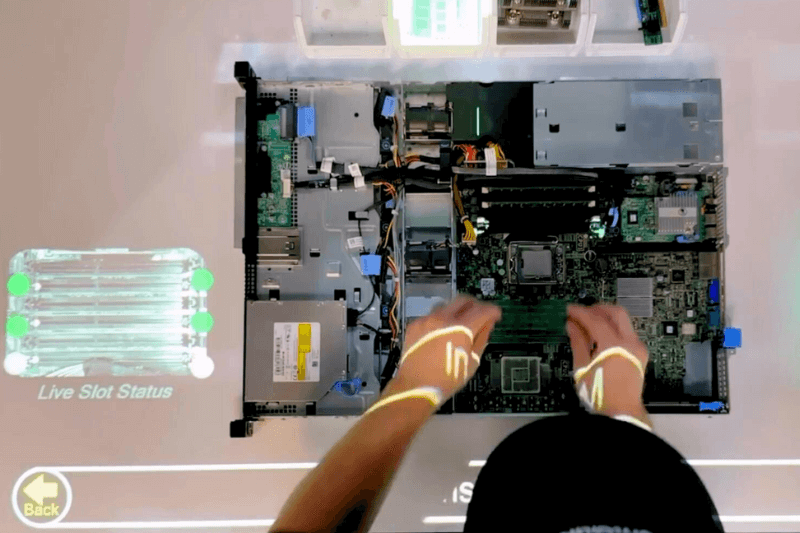

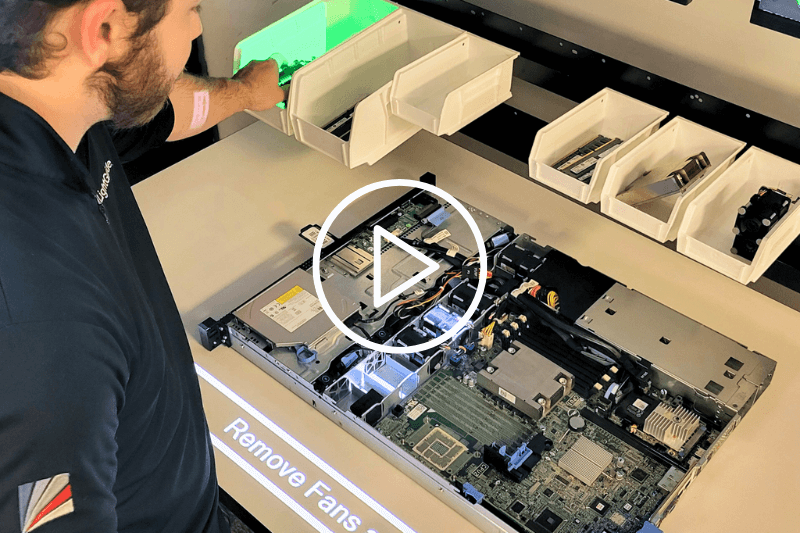

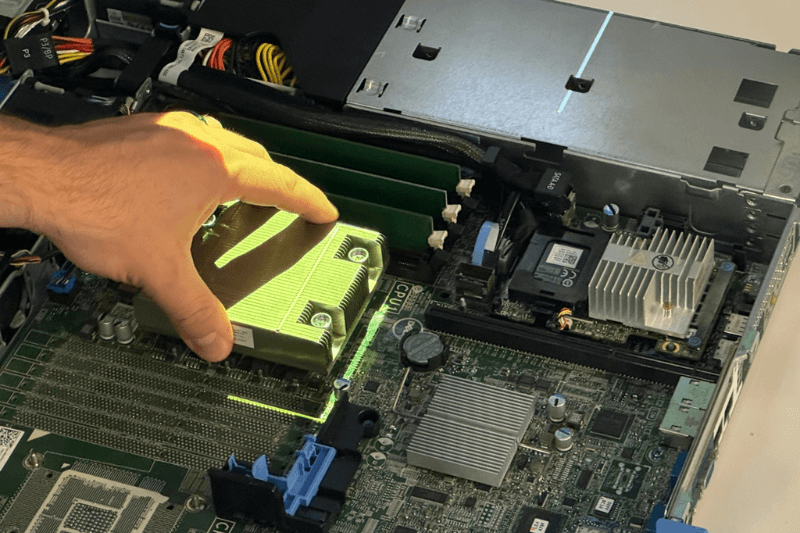

Watch how LightGuide brings precision and efficiency to server manufacturing with projected augmented reality (AR) work instructions. In this video, a technician performs a rack server assembly operation, guided step by step with AR overlays projected directly onto the physical device.

Real-Time Verification with Machine Vision and 3D Sensors

LightGuide integrates AI-powered machine vision and 3D sensors to verify each assembly step in real time. The system inspects every action—confirming accuracy before allowing progression—so errors are eliminated and consistency is maintained across the server assembly workflow. Illuminated bins further streamline component selection and placement, reducing wasted time and ensuring parts are always in the right place.

Data Capture for Traceability and Continuous Improvement

Beyond guidance, LightGuide captures critical operational metrics, including cycle time, step time, throughput, and defect logging. These datasets can be seamlessly connected to AI-enabled cloud platforms, providing traceability, insights into technician performance, and opportunities for continuous process improvement.

Driving Excellence in Server Manufacturing

LightGuide is transforming server manufacturing by combining AR guidance, automated verification, and data capture—delivering higher quality, faster production, and operational excellence at scale.