Achieve Proper Torque Values with Precise Sequencing Guidance

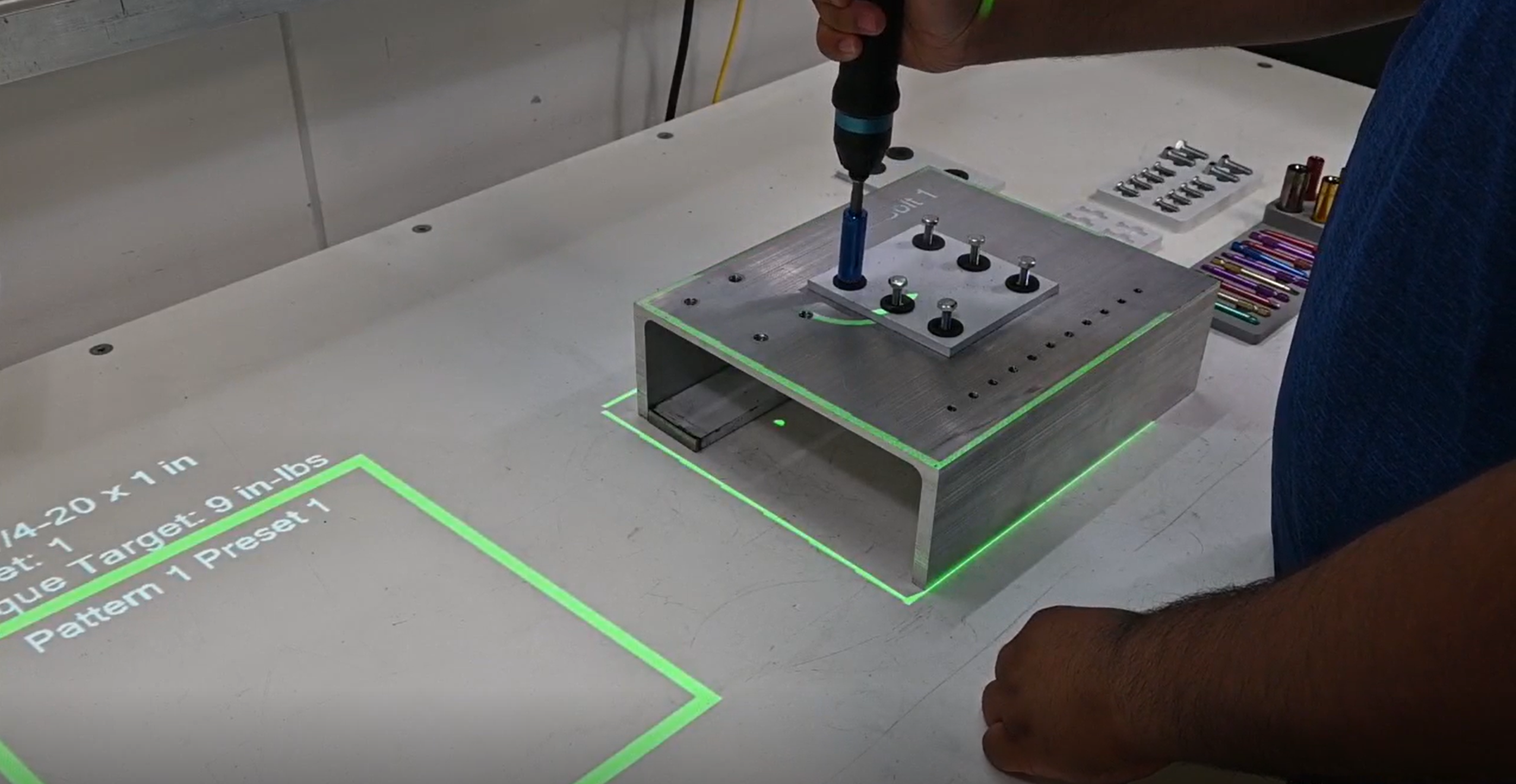

This video demonstrates how LightGuide’s projected augmented reality (AR) work instructions integrate with factory tools and IO devices, such as torque wrenches, to guide operators through a series of sequenced bolt patterns and confirm the proper torque is applied.

Projected AR work instructions show the operator what bolts to pick and provide additional bolt information, including bolt size, preset, and torque values, to the left of the work area. By adding videos along with text or static image instructions, operators can gain greater comprehension of a task. In this case, the video on the work surface outlines how the operator should attach sockets to the driver.

As the operator completes each torque, they are immediately shown whether they have achieved the proper torque value and correctly completed the task. If the torque value is incorrect, the operator is alerted by red text to the right, a red highlight on the work area, and an auditory cue.

At the end of the process, the operator sees a chart summarizing the real-time data collected throughout the process, plus their final cycle time. This data, along with other manual process data and insights like operator ID, step times, and more, are captured in LightGuide for full traceability.

Related Content:

LightGuide Torque Tool Integration

Connected Digital Manufacturing: Cobots and Augmented Reality