Connect Your Digital and Physical Twin on the Factory Floor

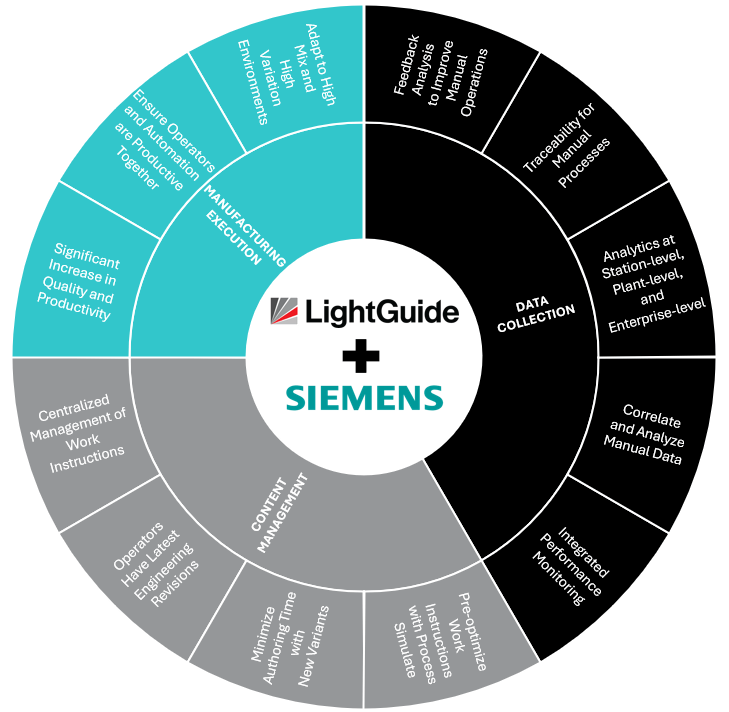

As a Siemens Alliance Partner, LightGuide integrates with Siemens Digital Industries Software—including Teamcenter, Process Simulate, Opcenter, Mendix, and Insights Hub—to connect the digital thread directly to manual operations on the factory floor.

By bringing intelligent AR-powered guidance and traceability to manual workflows, LightGuide provides the crucial link between your digital twin and physical execution, empowering smarter, more connected manufacturing operations.

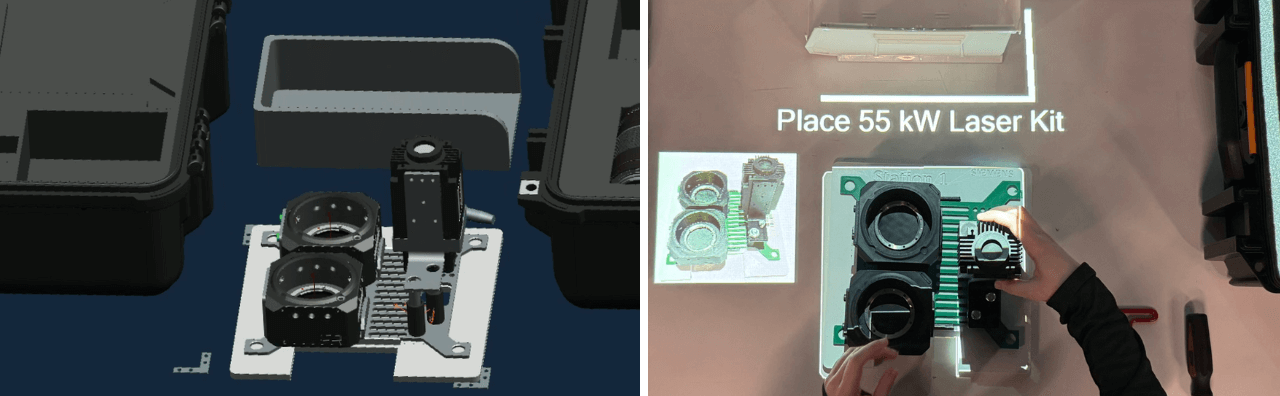

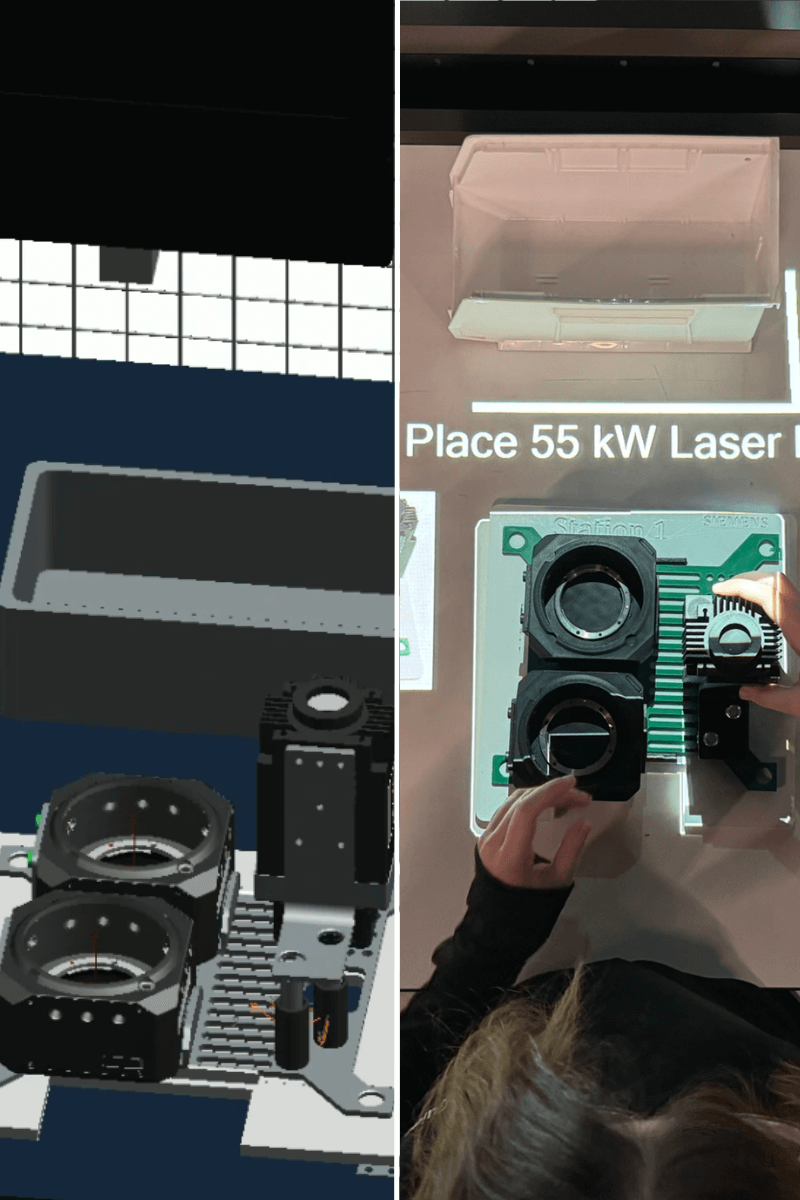

From Simulation to Reality: See How LightGuide and Siemens Process Simulate Bring the Digital Twin to Life on the Factory Floor

Watch how LightGuide integrates with Siemens Process Simulate to guide a gimbal assembly process with augmented reality work instructions and vision cameras. The LightGuide AR platform shows where each part goes, prevents defects before they happen, and ensures full traceability.

- Guide with precision: Empower workers with AR work instructions projected directly on the work surface.

- Proactively prevent errors: Improve quality with AI-driven vision systems that detect and prevent errors in real time.

- Unlock operational insights: Get real-time data and insights on operator performance and quality.

Video

Siemens Tools You Trust, Now Even More Powerful with LightGuide

Teamcenter

Leverage your Bill of Process repository in Siemens Teamcenter to generate augmented reality work instructions in LightGuide.

Process Simulate

Use Siemens Process Simulate to pre-optimize workflows and export steps and visuals directly to LightGuide, enabling AR-guided instructions powered by digital twin simulations.

Opcenter

Integrate LightGuide with the Opcenter Manufacturing Execution Systems (MES) to exchange real-time operation details and completion signals, ensuring synchronized production.

Industrial Edge

Securely transfer LightGuide’s workstation data to the Siemens cloud for centralized access and analysis.

Insights Hub

Aggregate, visualize, and analyze manual operations alongside automation data for comprehensive dashboards that enable smarter decisions.

Mendix

Custom Mendix apps can control and monitor LightGuide in real-time through our API, running workflows, querying production data, and managing users.

Where to Experience the Technology

LightGuide systems are deployed in collaboration with Siemens at advanced manufacturing facilities and innovation centers across the US, including MxD in Chicago, LIFT in Detroit, and The Smart Factory by Deloitte in Wichita.

Testimonials

"Based on our Siemens partnership, we've been able to take augmented intelligence to a whole new level by connecting digital processes with physical workflows to optimize manual processes."

Trusted by the World’s Leading Manufacturers to Deliver Results

|

|

|

|

|

|

|

|

|

|

|

|

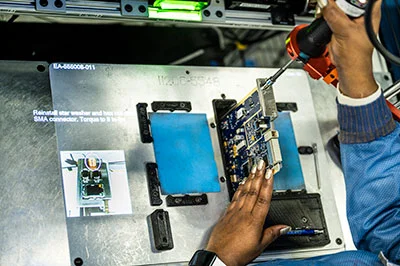

Aerospace & Defense Manufacturer Eliminates Defects with LightGuide

After implementing LightGuide’s augmented reality work instructions on a line with 17 variants, L3Harris eliminated defects and changeover per variant.

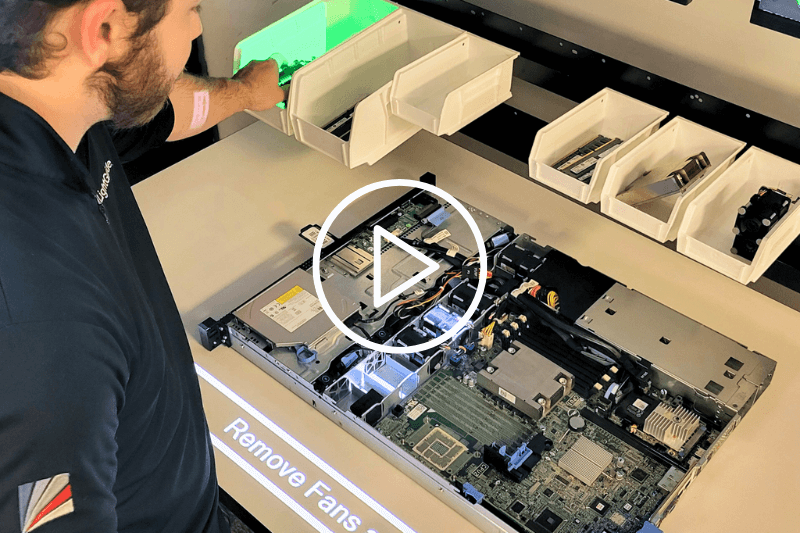

Augmented Reality-Guided Server Refurbishment

Watch how LightGuide’s augmented reality work instructions streamline and error-proof server maintenance, refurbishment, and assembly processes.

Simplify Complex Wire Harness and Cabling Tasks

No more deciphering diagrams or misplacing wires! Projected AR guides operators in real time to error-proof complex wire harness and cabling tasks.

Testimonials

"[LightGuide] reduces the reliance on operator memory – also known as “cognitive ergonomics” – effectively turning a complex process with multiple steps into a series of simple processes with single steps."

- 90%+ Quality Improvement

- 70%+ Training Efficiency

- 50%+ Productivity Increase