Trusted by the World’s Leading Manufacturers of Data Center Infrastructure

|

|

Seamlessly Combining Augmented Reality and AI for Server Manufacturing, Installation, and Break Fix

LightGuide combines projected AR with AI-powered machine vision, sensors, and smart tools to guide technicians with precise, real‑time visual instruction—eliminating guesswork, preventing errors, and ensuring every step is completed correctly the first time. By standardizing complex tasks, accelerating technician training, and improving throughput, our Augmented‑Intelligence platform helps data center operators scale capacity, boost uptime, and maintain consistency across global operations with confidence.

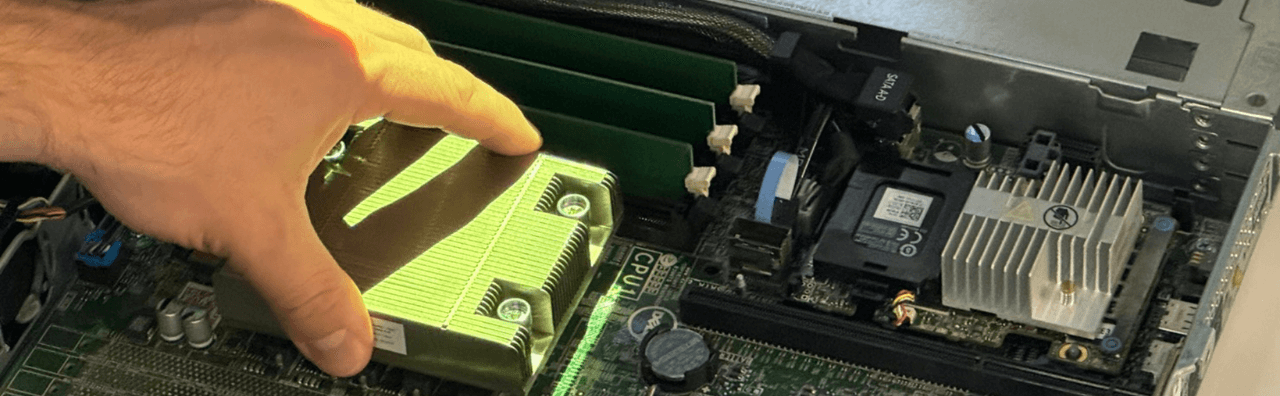

AR Guidance and Machine Vision Ensure Accuracy in Rack Server Assembly

Watch how LightGuide brings precision and efficiency to server manufacturing with projected augmented reality (AR) work instructions. In this video, a technician performs a rack server assembly operation guided step by step with AR overlays projected directly onto the device, while AI-powered machine vision and 3D sensors verify each action in real time.

Video

Error-Proof Server Installation and Cabling with AR

See how LightGuide simplifies server installation and cable routing with AR-guided work instructions and machine vision verification. From illuminating the correct rack bay for server placement to projecting step-by-step cable routing paths, LightGuide ensures every installation is accurate the first time. Real-time error detection, hands-free barcode scanning, and data capture for traceability eliminate mistakes, reduce downtime, and accelerate deployment across the data center.

Video

Using AR to Guide Data Center Cabling Operations

See how LightGuide simplifies data center cable management with AR-guided work instructions and machine vision verification. Technicians scan each cable hands-free and follow step-by-step overlays that highlight the correct port and routing path. Real-time error detection ensures every connection is accurate, while performance data capture supports traceability, compliance, and continuous improvement—reducing downtime and accelerating deployment at scale.

Video

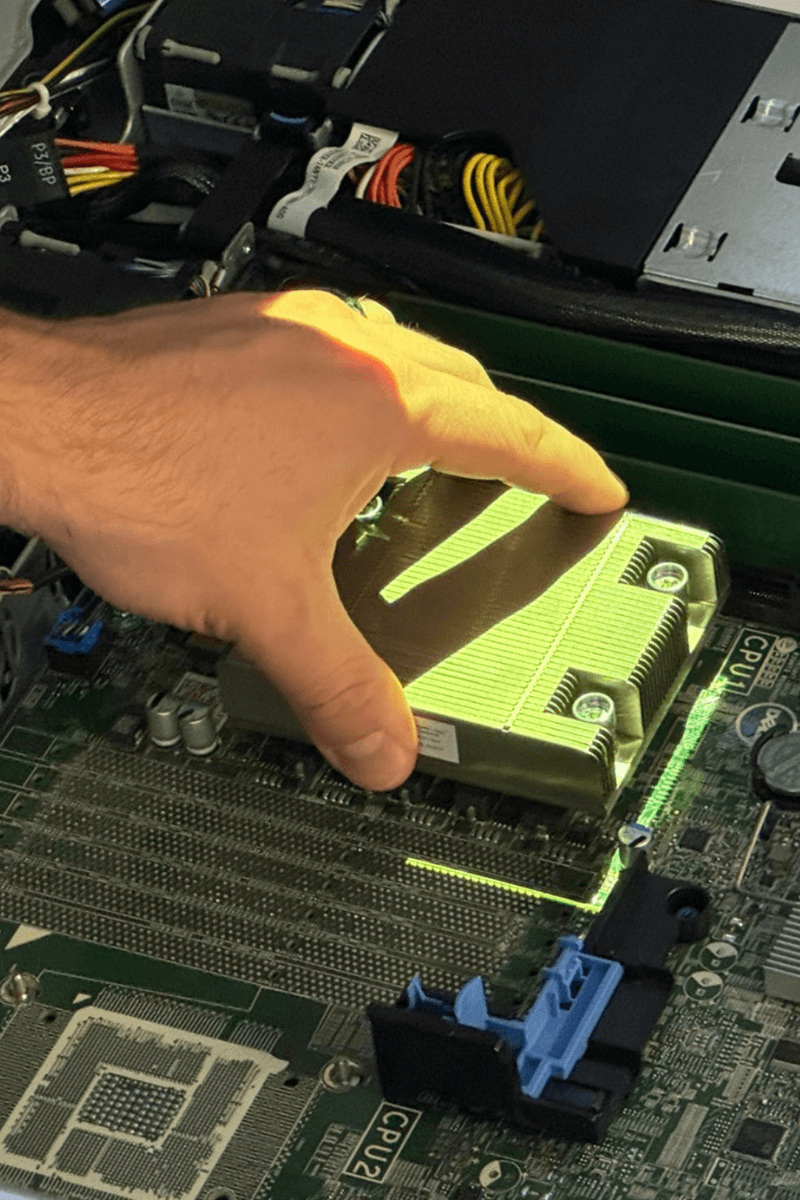

Using AR to Guide Break Fix Operations for Rack Servers

See how LightGuide streamlines data center break fix operations with AR-guided work instructions and machine vision verification. Technicians can instantly load the correct repair sequence, follow step-by-step overlays, and rely on real-time error detection to ensure accuracy. With guided parts picking and performance data capture, LightGuide improves repair quality, accelerates server break fix, and drives efficiency across maintenance workflows.

Video

LightGuide AR Delivers Proven Results

- 90%+ Quality Improvement

- 70%+ Training Efficiency

- 50%+ Productivity Increase

Your Guide to AR Applications on the Factory Floor

Not all types of augmented reality are created equal. Use this guide to discover which type of industrial AR is best suited for your factory application, learn from real-world case studies, and more.

|

|

Leading Manufacturers Have Dramatically Improved Their Processes. So Can You.

Aerospace & Defense Electronics Manufacturer Eliminates Defects

After implementing LightGuide AR work instructions on a line with 17 variants, L3Harris eliminated defects and changeover per variant.

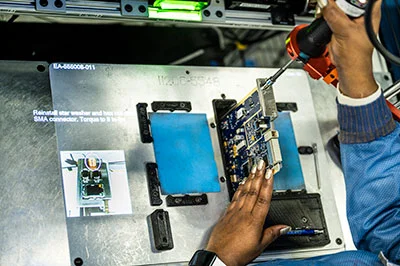

Tech Company Transforms Electronics Repair Processes with AR

Using projected AR, this company reduced complexity and standardized repair processes by digitizing workflows and providing technicians with precise visual guidance.

AR Work Instructions for Efficient & Error-free Electronics Assembly

From circuit boards to laptops to 5G wireless transmitters, AR work instructions visualize and error-proof manual workflows to provide operators with real-time guidance and confirmation for defect prevention.

Testimonials

"[LightGuide] puts work instructions exactly where you build your product, so you’re reducing time looking at printed instructions by putting the focus exactly where operators’ attention should be."

Let Us Design a Solution for Your Most Challenging Application

Ready to put the power of projected AR to work for you? Our proven platform, deployed across 200+ customers, can deliver predictable results for your most complex manual processes.