Improving Assembly Accuracy with Augmented Reality Guidance and Advanced Color Detection

Integrating augmented reality guidance with machine vision and collaborative automation streamlines even the most complex manual assembly processes, enhancing manufacturing efficiency and accuracy.

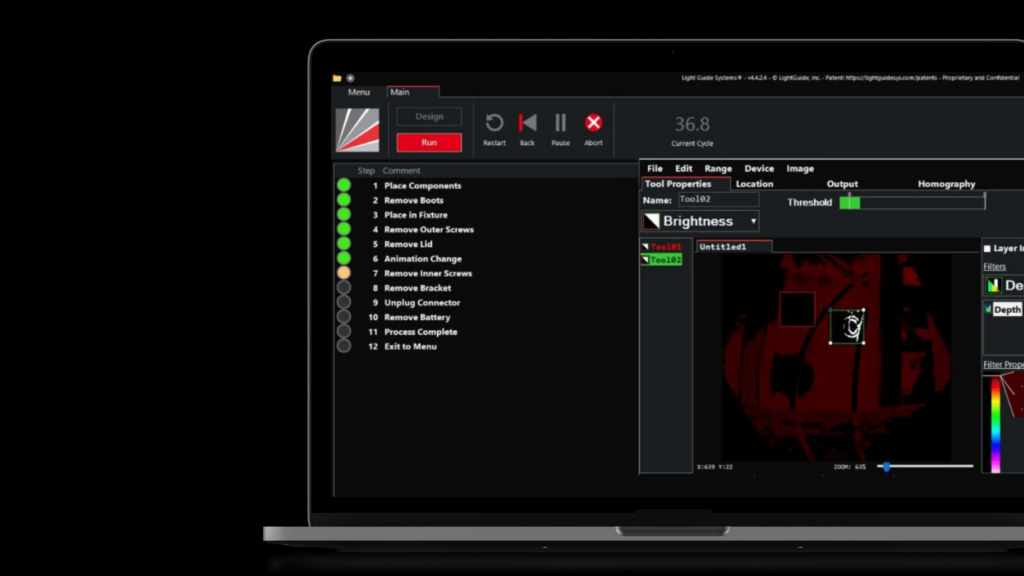

In this demo, LightGuide’s projected augmented reality work instruction platform delivers step-by-step visual guidance and AI-powered machine vision confirmation for real-time verification. Meanwhile, a KUKA LBR iisy cobot assists the operator with precise glue application.

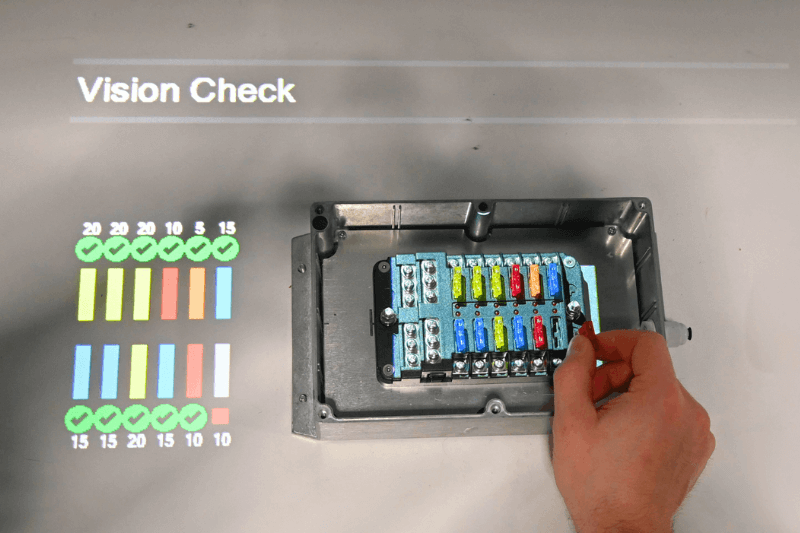

Here, the system projects digital work instructions directly onto the workstation, guiding the operator through tasks such as lid placement, fuse installation, and screw fastening. An integrated 3D sensor confirms correct part alignment, while advanced color detection ensures fuses are accurately placed. The system detects mistakes, such as placing fuses in the wrong location or selecting parts from the wrong bin, and provides feedback to help operators correct errors.

During the screw fastening step, a visible countdown timer is projected onto the work surface, helping operators maintain an efficient pace. Workers have the flexibility to pause the countdown as needed, allowing them to complete the task at their own speed while the system continues to collect data on step time and overall cycle time. This built-in functionality ensures both quality and adaptability, allowing operators to work at their own pace while supporting process optimization.

By merging augmented reality guidance with vision-based inspection and collaborative automation, manufacturers can achieve greater process control and reliably superior product quality.