Bring Your Digital Twin to Life with LightGuide AR and Siemens Process Simulate

What if your digital twin could do more than simulate manufacturing processes? What if it could guide real-world assembly on your factory floor?

That’s exactly what happens when LightGuide integrates with Siemens Process Simulate, transforming digital twin simulations into augmented reality (AR) guidance delivered directly on the line.

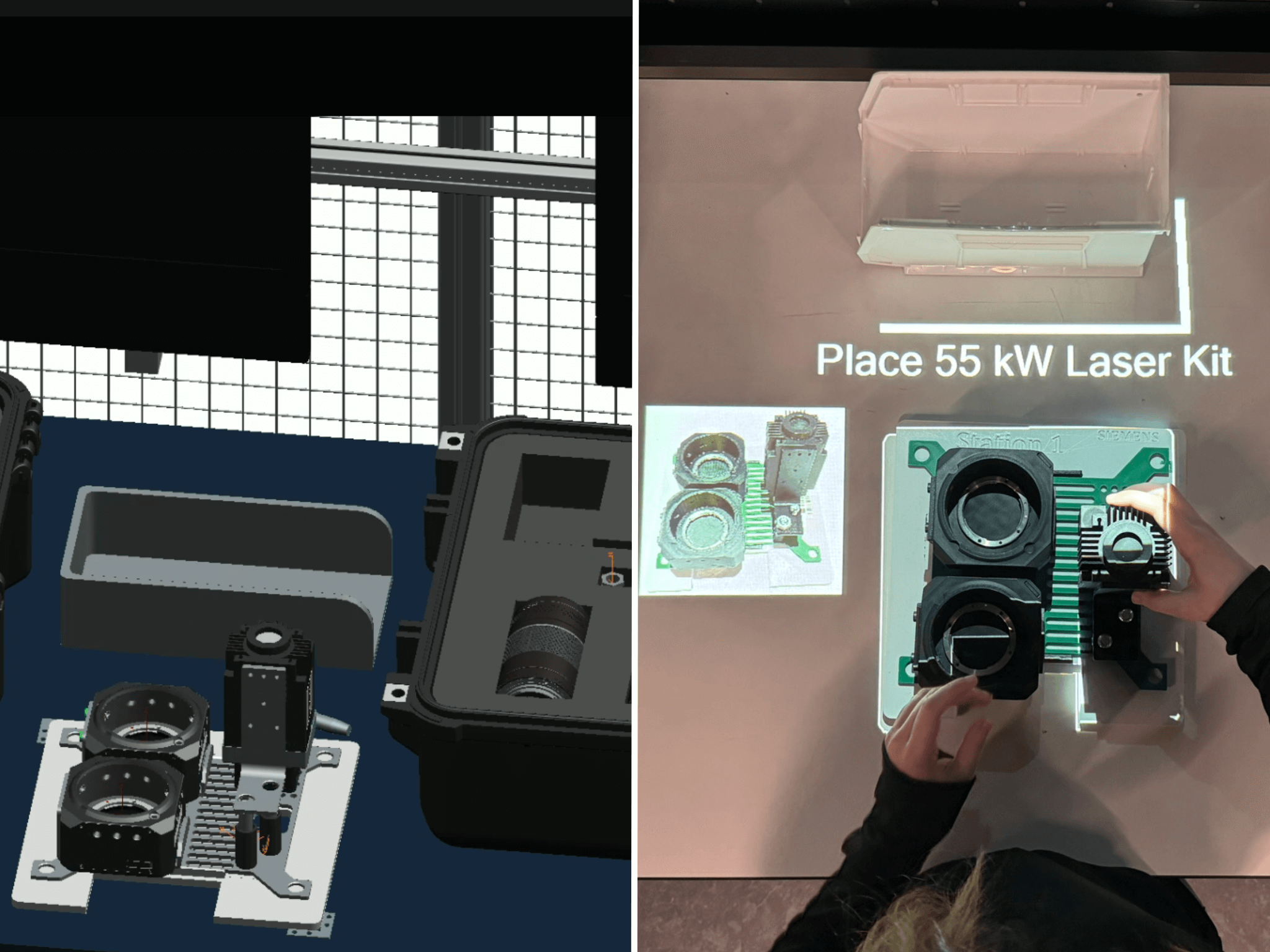

In this demo, LightGuide mirrors the Siemens Process Simulate workflow for assembling a gimbal, projecting step-by-step AR work instructions onto the workstation in real-time to guide operators with precision, speed, and confidence.

Step-by-Step AR Guidance on The Factory Floor

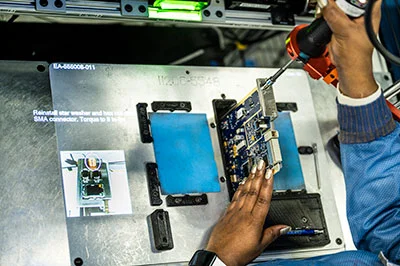

Projected AR work instructions guide the operator through each step of the process, showing the correct part placement in the proper sequence to ensure process adherence from the start.

Real-Time Confirmation for Error-Prevention

Using 3D vision cameras, LightGuide confirms each action has been completed correctly, flagging any errors in real time to prevent defects from moving downstream.

Data Capture for Enhanced Traceability

As each step is performed, key operational metrics are captured at the point of execution, enhancing traceability and delivering full visibility into manual operations.

This seamless connection between digital simulation and physical execution delivers an efficient, repeatable assembly process for complex manual operations.

Seamless Integration Across Siemens Solutions for Smarter Manufacturing

This is just one example of how LightGuide’s projected AR platform can bridge the digital-physical gap to improve frontline performance.

As a Siemens Alliance Partner, LightGuide integrates across the Siemens Digital Industries Software—including Process Simulate, Teamcenter, Opcenter, Mendix, and Insights Hub—to connect design, execution, and analysis in one intelligent loop.

Whether you’re aiming to improve training, quality, or productivity, LightGuide is paving the way for the next generation of connected manufacturing by transforming complex manual processes into efficient, traceable workflows.