The Power of Product Traceability in Manufacturing

Traceability is critical to improving processes across every manufacturing industry. It stands out in sectors with high quality and liability standards, but traceability is becoming equally important to increasing efficiency, quality, and throughput in every manufacturing sector.

From product, to internal, to supply chain traceability, having high-level tracing processes means organizations gain a deeper look at their production processes and can assert more control over their performance. This granular view of operations data equips manufacturers with the information needed to improve processes at an individual workstation, factory and enterprise level.

Below, we’ve put together a guide to explain what traceability is, the types of traceability in manufacturing, and four ways manufacturers can use traceability data to optimize operations.

What is Traceability?

Traceability, also known as product traceability, is the capability to find and verify the complete history of production parts. Everything from the moment an employee scans in to start their shift to the product arriving in receiving can be tracked, analyzed, and reported.

Data collection and analysis are imperative to agile manufacturing and continuous improvement. Collecting the right data enables full traceability and understanding of your process.

To understand the power of the data you collect, let’s break down the two types of traceability.

What is Internal Traceability?

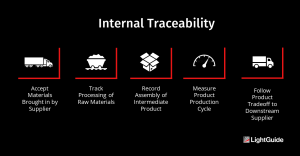

Internal traceability is the process of tracking parts through their processes within one company or plant.

Internal traceability tells the story of how raw materials come into a plant, are manufactured into intermediate products, and then become final products. It includes the acceptance records, internal process records, and shipment records. Once this collection of data is aggregated, it shows the full production process of a part.

Then, when Industry 4.0 software is integrated, that data can be further analyzed. For example, enterprise augmented reality technology, like LightGuide’s AR software, doubles as a traceability software solution that provides manual process data such as right and wrong bin picks, step times, proper inspections, and correct part placement.

What is Supply Chain Traceability?

Whereas internal traceability tracks parts within the company or factory, chain traceability tracks parts as they move throughout the supply chain. This type of traceability provides additional awareness of the full product process and delivery, increasing quality tremendously.

To visualize supply chain traceability, imagine an automotive headliner moving from a Tier 1 supplier to an OEM. The same Tier 1 factory may be working on multiple types of headliners. When headliners are transported from the factory, manufacturers need to trace exactly what left the factory and the sequence it was in. If a set of headliners arrive and is damaged in transport, it decreases throughput and causes issues in-between the supplier and OEM.

With full chain traceability, the Tier 1 supplier can prove the condition of parts leaving their factory. Adding augmented reality to automotive manufacturing with tools like LightGuide’s AR software provides the assurance tiered suppliers and OEMs are looking for. Its snapshot feature can provide absolute proof of part quality—with an added timestamp—anywhere in the process.

Why is Traceability Important in Manufacturing?

Traceability gives manufacturers real-time visibility into their operations that can dramatically improve quality and production efficiency. There are four ways traceability supports continuous improvement and more efficient manufacturing.

1. Traceability Puts Data into Context

On its own, individual data points can be hard to understand. However, with full traceability, that data can be compiled into reports and dashboards that paint a more complete picture of your process and the individual products that pass through it.

For example, modern digital platforms and devices, like MES and PLC systems, are capable of recording all kinds of traceability data including:

- Cycle times

- Operator IDs

- Barcode scans

- Gauge values

- Serial numbers

- Dates and times that operators began and completed work

Each of these is critical to measuring the success of your process. Compiling these individual data points within agile software provides a way to visualize how all of these data points combine to evaluate a whole (i.e. your production process). Looking at it as a system provides insight into where your successes and challenges lie.

2. Traceability Improves Quality

Once recurring problems and inefficiencies are recognized, factory-level metrics can be improved, especially quality. Traceability within quality control helps you to contain defective parts that were caused by a batch of raw materials, a faulty production machine, or a design defect. After you find the first bad part, you can look up all other parts that might share the problem and proactively find and repair all affected parts.

In addition to making it easier to identify the root cause of defects after the fact, product traceability efforts also promote accountability in your process and in the operators that help make that process happen.

For instance, having an operator scan their employee badge at the station when they start their shift can remind them of their responsibility for making sure they are performing their job correctly and with the care the product, and your customer, deserve.

Luxottica, “a leader in the design, manufacture, and distribution of fashion, luxury, and sports eyewear” implemented LightGuide’s AR software to error-proof sequencing and ensure cleanliness. As a supplement to the work instructions provided, LightGuide’s AR software provided a holistic view of the errors across the factory with traceability of manual processes. Overall, Luxottica yielded a 19% decrease in defects.

3. Traceability Informs Better Decision Making

Data and reports generated to prevent defects can also be used to identify bigger problems with a process, such as excessively time-consuming and costly activities.

Fully contextualized data may also reveal problems that are difficult to identify with the data of a single device alone. Patterns can emerge that display challenges operators face, such as unnecessary actions that create an ergonomic hazard or safety issue with a task.

Related Article: What Is Ergonomics?

When operators are required to perform unnecessary or overly difficult tasks, they will find ways to make the task easier for themselves, sometimes in ways that are unsafe or cause quality issues. Identifying these problems makes it easier to solve them, meaning that operators can do their work effectively and comfortably.

4. Traceability Makes Compliance Possible

Some industries, such as aerospace, defense, and medical device manufacturing mandate traceability in all of their processes. It’s imperative to know where a product has been, whose hands it has passed through, and that every step of the process was performed properly and safely.

Even in the case of industries that do not mandate traceability as a part of their regulations, having a fully traceable product promotes trust and improves the reputation of the product with its customers.

Related Article: 6 Uses of Augmented Reality for Manufacturing In Every Industry

In many cases, OEMs may mandate full traceability of their supplier’s processes to achieve full traceability of their own products. As mentioned in the automotive headliner example above, a traceable process can also be used to determine whether or not quality problems may have occurred in other parts of the supply chain. Being able to identify this protects suppliers from liability for problems they did not cause.

Similarly, for companies that rely on products from many suppliers, traceability requirements can allow them to better understand where the components that make up their products have been, making them better able to ensure the quality of their products to their customers.

A Fully Traceable Future with Augmented Reality

Traceability is giving a new perspective to every industry in manufacturing. As the world becomes more connected, more information becomes available. To stay competitive, manufacturers need to understand every aspect of a given process. Luckily, we are now able to view our processes on an enterprise scale. Overall, this leads to rapid problem solving and continuous improvement.

By adding augmented reality to the process, with tools like LightGuide’s AR software, manual data can unlock more traceability throughout operations. The aspects of manual processes that were difficult to track or challenging to improve, are now accessible and leading to higher quality, efficiency, and throughput.

To find out how AR can enhance traceability and process improvement in your organization, set up a consultation with one of our manufacturing experts.