How AR-Powered Digital Work Instructions Drive Operational Excellence in Manufacturing

From Paper to Progress: The Transition to Digital Work Instructions

For generations, the hum of machines in factories was accompanied by the rustling of paper. Work instructions guiding every step of production were etched on these fragile pages, prone to wear and tear, misunderstandings, and human error. The result? Inconsistent quality, wasted time, and inefficient workflows that held back productivity and innovation.

Over time, paper-based instruction manuals were replaced by digital work instructions. Today, digital technology is sweeping through manufacturing floors, replacing paper with interactive screens, mobile devices, and even augmented reality.

Digital work instructions provide a way for manufacturers to streamline their processes and improve efficiency. By using digital workflows, manufacturers can reduce the amount of time it takes to train new employees and can ensure that all employees are following the same procedures.

In This Article

- What are Digital Work Instructions?

- Digital Work Instructions, Smart Factories, and Industry 4.0

- How to Create Effective Digital Work Instructions

- Common Use Cases for Digital Work Instructions

- Going Beyond the Screen with Augmented Reality Work Instructions

- Why Projected AR is the Future of Digital Work Instructions

What are Digital Work Instructions?

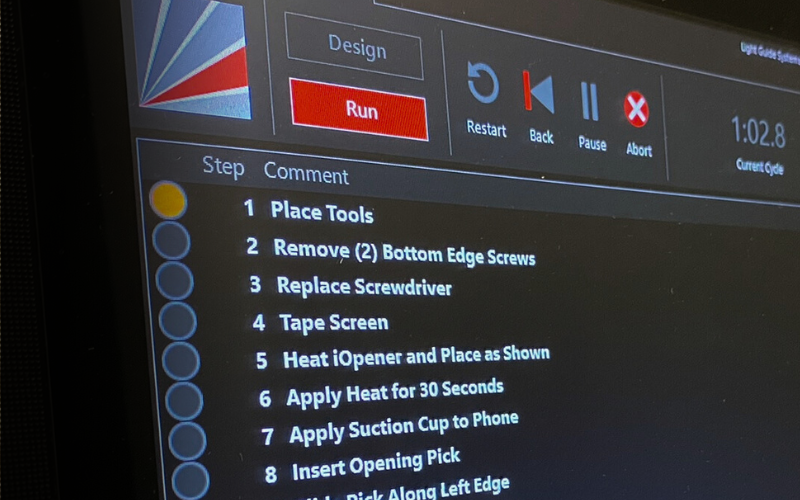

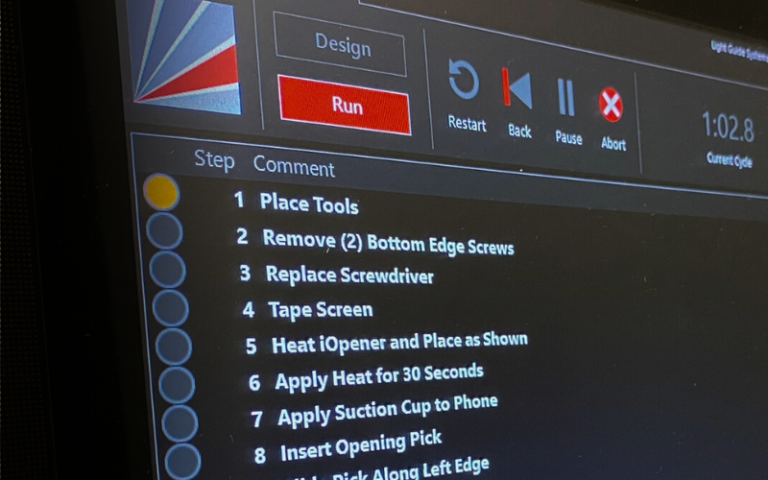

Digital work instructions are electronic versions of work instructions and standard operating procedures (SOPs) that transform static printed documents into dynamic, interactive tools. They guide workers through complex processes in manufacturing, maintenance, and service by providing real-time, step-by-step directions (complete with visual aids and contextual information) on the best way to complete a task. These digitized instructions and work procedures are kept in a centralized system so workers can easily access them to work on tasks or make decisions on projects.

Key Advantages of Digital Work Instructions

- Digital work instructions are paperless work instructions accessible through an electronic device, such as a PC, monitor, tablet, smartphone, or augmented reality device. They provide relevant step-by-step information in an easily digestible and visual format, replacing outdated paper-based procedures.

- They help frontline workers perform any task that requires following a standard operating procedure (SOP) – from assembly to inspection to maintenance.

- Digital work instructions are as much about knowledge transfer as they are about process documentation.

- They can be customized to meet the needs of individual workers and can be used to collect data on worker performance.

- Digital workflows can be augmented with visual aids, contextual information, and AR experiences to help intelligence.

Digital Work Instructions, Smart Factories, and Industry 4.0

Digital work instructions are a cornerstone of Industry 4.0, integrating seamlessly with other digital transformation initiatives. They enable smart manufacturing practices by facilitating real-time data sharing and analysis, enabling better decision-making and process optimization.

They provide a way for manufacturers to streamline their processes and improve efficiency. By using digital work instructions in their smart factories, manufacturers capture tribal knowledge from their experts, reduce the amount of time it takes to train new employees, and ensure that all employees are following the same procedures.

Digital work instructions can also be used to collect data on worker performance, which can be used to identify areas for improvement. According to global consultancy EY, “Manufacturers can use digital to more easily and effectively capture and convert tribal knowledge into institutional knowledge that stays with the company, and can be more broadly leveraged across the company.”

How to Create Effective Digital Work Instructions

Creating digital work instructions is an essential step toward modernizing and streamlining operations in various industries. This process involves the transformation of traditional, often paper-based, instructions into dynamic, digital formats that are more accessible, interactive, and adaptable. The creation of these instructions is not just about digitizing content, but also about enhancing the way information is communicated to the workforce.

Here are five tips for creating high-quality digital work instructions that are not only effective but also user-friendly and impactful:

1. User-Centric Design

Tailor the instructions to the end user’s perspective, considering their skill level and familiarity with the task. Use clear, concise language and avoid technical jargon to ensure comprehension across all skill levels.

2. Incorporate Multimedia Elements

Use images, videos, and interactive elements to make complex instructions more understandable. Visual aids can significantly enhance learning and retention compared to text-only instructions.

3. Ensure Accessibility

Make sure digital instructions are easily accessible to workers. When workers can easily find and understand the instructions they need, they can complete tasks faster and with fewer errors. This translates to reduced downtime, improved output, and overall production efficiency.

4. Regular Updates and Feedback Loops

Keep the content up to date with regular revisions and incorporate feedback from users to continuously improve the instructions. Processes and technologies evolve, so regularly reviewing and updating instructions ensures they reflect current procedures, best practices, and equipment.

5. Track Usage and Effectiveness

Implement analytics to track how the instructions are being used and their impact on task performance. Completion times, error rates, and other performance metrics can be used to assess the impact of instructions on efficiency and quality. This can help inform decisions about streamlining steps, reorganizing information, or adapting delivery methods for better retention and comprehension.

Take your digital work instruction authoring to the next level with these valuable resources:

- 6 Tips for Writing Practical Work Instructions

- 3 Ways AR Makes it Easier to Write Digital Work Instructions

Common Use Cases for Digital Work Instructions

Digital work instructions are transforming the industrial landscape, empowering frontline workers with instant access to clear, concise guidance right at their fingertips. This data-driven approach streamlines processes, boosts quality, and unlocks a new level of operational efficiency across diverse use cases.

Let’s explore 10 ways digital work instructions are making an impact:

1. Assembly Line Operations

Guiding workers through complex assembly processes with step-by-step instructions, improving quality and throughput.

2. Quality Control

Ensuring consistent quality checks and compliance with industry standards.

3. Employee Training and Engagement

Accelerating the learning curve for new employees with interactive and engaging instructional content.

4. Safety Procedures

Ensuring workers follow safety protocols and guidelines, reducing the risk of accidents and injuries.

5. Standardization

Standardizing work processes and ensuring everyone follows the same procedures to reduce the risk of errors.

6. Inventory Management

Streamlining inventory processes with clear guidelines for material handling and storage.

7. Machine Setup and Calibration

Ensuring precise setup of machinery for optimal operation.

8. Maintenance and Repairs

Providing detailed procedures for equipment maintenance, reducing downtime and errors.

9. Field Service Management

Offering remote support and guidance to field technicians from any location.

10. Environmental Compliance

Educating workers on practices that comply with environmental regulations and sustainability goals.

Beyond the Screen: Augmented Reality Work Instructions

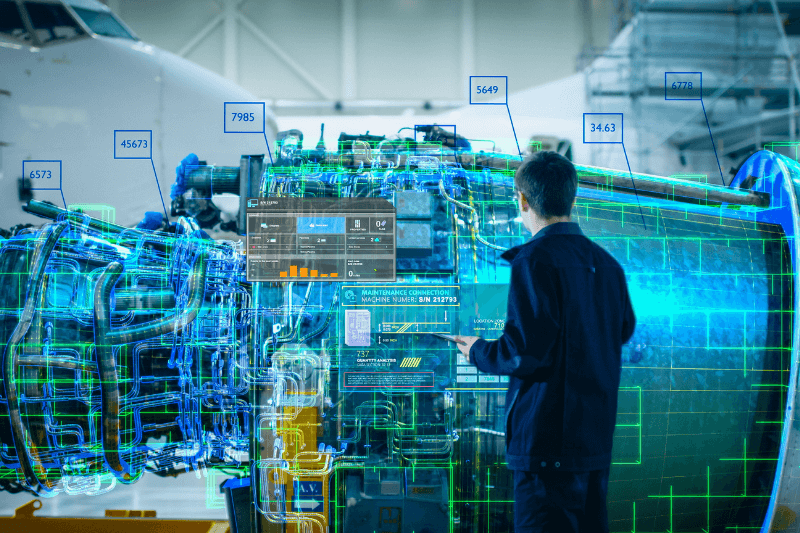

Digital work instructions are now evolving into augmented reality (AR) work instructions, signifying a major advancement in industrial efficiency. By overlaying digital data onto the physical world, AR adds an immersive aspect to digital instructions, enhancing how workers interact with complex tasks.

These digital workflows, displayed via AR headsets, mobile devices, or digital projection offer a highly intuitive way to complete tasks, merging virtual and real-world elements to simplify procedures and reduce errors. Interacting with instructions directly on the work surface for the task at hand leads to reduced cognitive load and improved accuracy for frontline workers.

Key Benefits of Augmented Reality Work Instructions

- Increase Productivity and Efficiency: Streamline SOPs with real-time, step-by-step AR guidance, reducing cycle times and boosting throughput.

- Enhance Quality and Accuracy: By overlaying digital work instructions onto the physical world, AR ensures precise execution of tasks, dramatically reducing the likelihood of errors and enhancing overall quality.

- Streamline Training and Upskilling: AR offers hands-on, interactive training experiences for employees, allowing them to learn complex processes quickly without risking mistakes on actual workpieces.

- Improve Safety: By providing clear, visual instructions, AR work instructions can help ensure safety protocols are followed precisely, reducing the risk of accidents in the workplace.

- Facilitate Remote Collaboration: AR enhances remote collaboration, allowing workers to learn how to operate equipment through interactive instructions and get visual guidance in context.

- Foster Data-Driven Decision Making: Gain real-time insights into worker performance and process adherence, identifying areas for improvement.

- Integrate with Existing Factory Systems: AR workflows can be seamlessly integrated with existing enterprise systems including PLCs, sensors, and smart tools for automated process control.

Why Projected AR is the Future of Digital Work Instructions

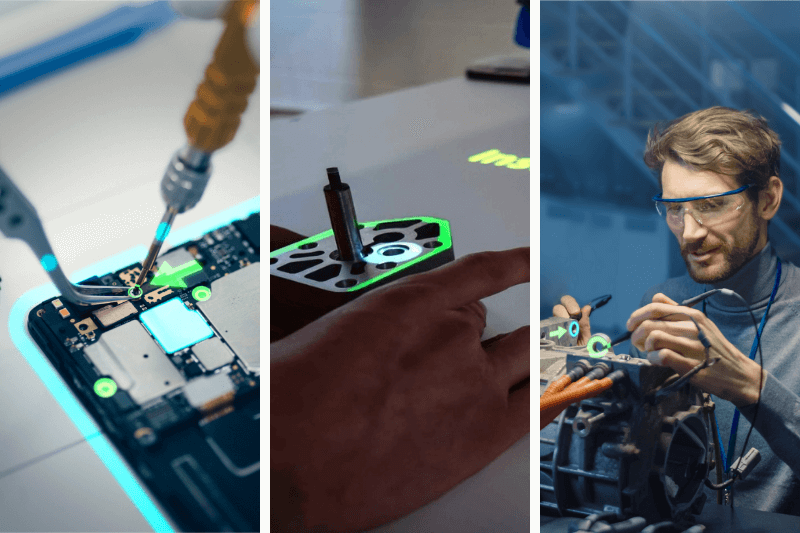

Projected augmented reality work instructions like LightGuide take AR to the next level, overlaying instructions directly onto work surfaces without the need for wearable or handheld devices.

This innovative technology enhances accuracy and speed, as workers no longer need to shift their focus between instructions and their work surface. Integrated with 3D sensors and vision cameras, the system can detect and prevent errors in real-time, while capturing key operational data.

Explore how LightGuide projected AR work instructions can transform your operations:

Improved Focus and Productivity

Instructions, diagrams, and essential details are projected directly onto workspaces using a hands-free, focused approach. This keeps employees concentrated and actively engaged, minimizing any potential distractions.

Comfort and Practicality

Unlike wearable AR devices that can cause discomfort from eye strain, dizziness, and nausea, projected AR work instructions are ergonomic and don’t require battery charging, making them well-suited for extended use in manufacturing environments.

Enterprise-Ready Integration

Integrating projected AR with factory tools, like 3D sensors, vision cameras, and torque tools, is seamless and secure, providing an additional layer of connectivity that provides workers with real-time guidance and confirmation.

Always-On Reliability

Projected AR systems are built to last, powered directly by a line connection, and free from the limitations of battery use. They are designed to support round-the-clock manufacturing processes and can withstand the most challenging industrial conditions, ensuring reliability in environments with dust, noise, or other potential hazards.

Take a deeper dive into LightGuide projected AR work instructions

The benefits of projected augmented reality work instructions are proven and undeniable. Let’s explore several case studies from different industries to see the power of projected AR work instructions in action:

- Global aerospace and defense manufacturer, L3Harris Technologies, eliminated changeover per variant and achieved zero assembly-related defects on a complex manual line. Read the full case study.

- Battery-electric van, truck, and bus manufacturer, Lightning eMotors, uses AR work instructions to decrease cycle time by 50% and training time by 75%. Explore the case study here.

- This global consumer electronics leader is using LightGuide AR work instructions in their e-waste recycling processes. Learn more here.

The Future of Digital Work Instructions in Manufacturing

The transition from paper to digital work instructions is not just a technological upgrade; it is a paradigm shift. By empowering workers with real-time information, interactive guidance, and AR overlays, digital technology is ushering in a new era of efficiency, precision, and innovation in manufacturing. Digital work instructions are transforming all factories into the smart, digital factories of Industry 4.0.

This is just a glimpse into the exciting world of digital work instructions. As technology evolves and industry leaders continue to embrace its potential, the possibilities seem limitless. The future of manufacturing is here, and it’s written in code, not on paper.

Explore the power of the LightGuide AR platform

Ready to Explore How Projected AR Work Instructions Can Give Your Workforce a Competitive Advantage?

Connect with our team to see how the LightGuide platform can transform your operations.