What is a Smart Factory? A Guide to Smart Manufacturing

The Integration of Technology and Human Ingenuity in Smart Factories

Envision a factory of the future, where the seamless integration of cutting-edge technology with skilled human expertise creates an environment of unparalleled productivity and innovation. This vision is the heart of smart factories, where the digital transformation of the industrial landscape is not just a dream but a reality.

This comprehensive guide explores the intricate workings of smart factories, a cornerstone of Industry 4.0, offering profound insights into smart manufacturing. Here, technology does not replace human effort; it elevates it, enabling workers to achieve new heights of efficiency, quality, and problem-solving.

In this article:

- What is a Smart Factory?

- The Pillars of Smart Manufacturing

- Smart Factory Technologies

- Benefits of Transitioning to a Smart Factory

- The Four Evolutionary Stages of Smart Factories

- Challenges and Considerations

- Real-World Use Cases and Success Stories

- Future of Smart Manufacturing

- Smart Factories that Elevate Human Potential

What is a Smart Factory?

At its core, a smart factory is a shift from traditional manufacturing to an interconnected, intelligent system. This ecosystem features machinery and equipment that self-optimize, self-adapt, and make autonomous decisions, driven by a synergy of advanced technologies.

The transition from traditional to smart manufacturing is not just about technology implementation; it’s a rethinking of processes, workflows, and management philosophy. Smart factories stand apart in their ability to respond quickly to market changes, manage resources efficiently, and deliver unparalleled customization.

The Pillars of Smart Manufacturing

Smart manufacturing stands on several foundational pillars, each integral to its functionality:

- IT and OT Integration: A seamless blend of software and hardware that forms the backbone of a smart factory, enabling efficient communication and control.

- Automation and Robotics: Enhance efficiency and reduce human error by automating tasks and processes, leading to higher productivity and quality.

- Data Analytics: The cornerstone for predictive maintenance, process optimization, and informed decision-making, driving continuous improvement.

- Digital Twin and Cyber-Physical Systems: The fusion of physical operations with digital technology, creating interconnected systems that monitor and control physical processes.

- Cloud Computing and IoT: Essential for real-time data processing and global connectivity, enabling remote monitoring and control of manufacturing operations.

Smart Factory Technologies

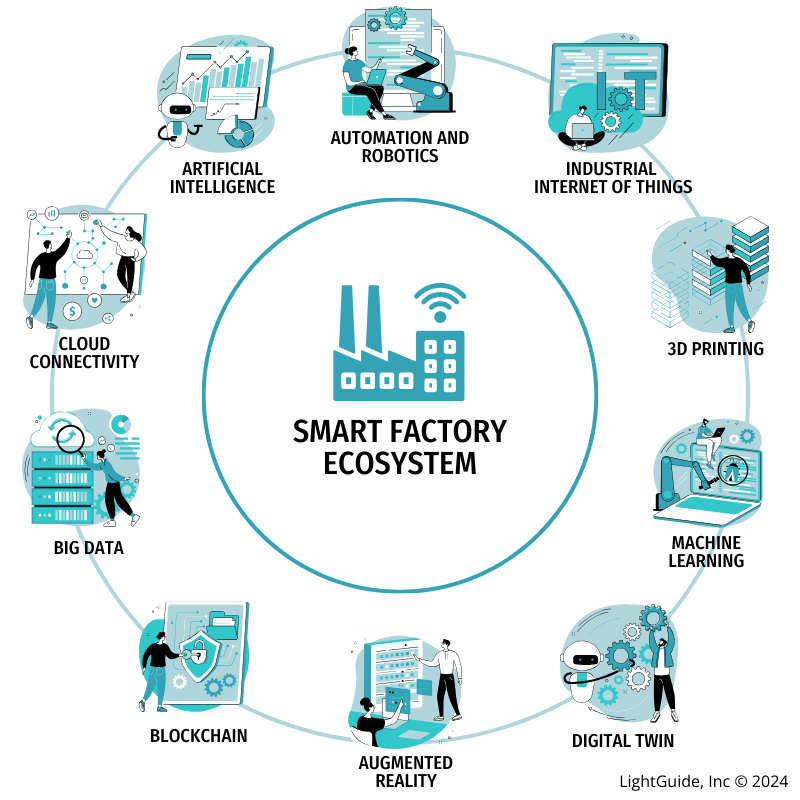

In the realm of smart manufacturing, a suite of cutting-edge technologies converge to transform traditional factories into smart factories. Each of these technologies plays a crucial role in enhancing efficiency, accuracy, and adaptability in manufacturing processes.

Cloud Connectivity

Cloud connectivity in smart manufacturing utilizes cloud computing to store, process, and manage data, offering unparalleled scalability and flexibility. This strategic use of cloud technologies enables centralized data storage and real-time data processing, essential for responsive and efficient manufacturing operations.

Impact: The impact of cloud connectivity extends beyond basic data management. It significantly reduces infrastructure costs and enhances collaboration by seamlessly integrating various systems and processes. With advanced analytics and AI capabilities, cloud platforms provide deep insights for performance optimization and predictive intelligence. Additionally, the scalability and elasticity of cloud services allow for rapid adaptation to changing market demands. Robust security measures and compliance standards inherent in cloud services ensure data safety and privacy, making cloud connectivity a transformative force in the digital manufacturing landscape.

Big Data

Big data refers to the collection, processing, and analysis of vast and complex data sets generated throughout the manufacturing process. This encompasses data from various sources, such as machinery performance, production rates, quality control metrics, and supply chain operations. The capacity to handle such extensive data is crucial for extracting meaningful insights and driving efficient manufacturing practices.

Impact: The impact of big data in smart factories is profound and multifaceted. By harnessing these large data sets, manufacturers can achieve predictive maintenance, reducing downtime and prolonging equipment life. It enables more informed decision-making, leading to optimized production processes and enhanced product quality. Big data analytics also play a pivotal role in supply chain optimization, forecasting demands, and managing inventory more effectively. Furthermore, the insights gained from big data analytics facilitate continuous improvement and innovation, ensuring manufacturers can quickly respond to market trends and customer needs. In essence, big data transforms raw data into strategic assets, providing a competitive edge in the rapidly evolving manufacturing sector.

Industrial Internet of Things (IIoT)

The Industrial Internet of Things (IIoT) refers to the network of interconnected sensors, machines, and devices integrated into the manufacturing environment. This technology enables the collection and exchange of vast amounts of data across various points in the manufacturing process, from the supply chain to the production floor.

Impact: IIoT transforms manufacturing operations by enhancing real-time visibility and control over processes. This connectivity leads to significant improvements in efficiency, productivity, and safety. By leveraging IIoT, manufacturers can monitor equipment performance, predict maintenance needs, and minimize downtime. It also enables the automation of complex processes, improving accuracy and reducing human error, and facilitates the customization of products to meet specific customer demands, enhancing overall operational agility.

Digital Twins

Digital twins involve creating a virtual replica of a physical manufacturing system or process. This digital model is continuously updated with data from its physical counterpart, allowing for real-time simulation, analysis, and optimization of manufacturing processes.

Impact: The use of digital twins enables manufacturers to test and refine processes in a virtual environment before implementing them in the real world. This leads to improved product design, enhanced production efficiency, and reduced time to market. Digital twins also assist in predicting potential issues, allowing for preemptive measures, and play a crucial role in training and development, providing a safe and cost-effective way to simulate scenarios and train personnel.

Artificial Intelligence (AI)

Artificial Intelligence involves the simulation of human intelligence processes by machines, especially computer systems. This includes learning from data, reasoning, and self-correction. AI in manufacturing is applied to automate complex tasks, enhance decision-making, and optimize production processes.

Impact: AI’s impact on manufacturing is transformative, leading to increased efficiency and reduced downtime. It enables predictive maintenance, quality control, and enhances the capabilities of robotics on the production line. AI-driven insights help manufacturers make smarter decisions, leading to cost savings and increased productivity. Moreover, AI can identify patterns and trends, driving innovation and helping businesses stay ahead in a competitive market.

Machine Learning (ML)

Machine learning, a subset of AI, enables systems in a manufacturing setting to learn and improve from experience without being explicitly programmed. It involves algorithms that can analyze data, learn from it, and make informed decisions based on the insights gained.

Impact: In smart manufacturing, machine learning significantly enhances predictive maintenance and quality control. It allows for real-time adjustments in production, reducing waste and improving product quality. Machine learning algorithms can optimize supply chain management, foresee production bottlenecks, and adjust operations accordingly. This results in streamlined processes, improved efficiency, and a more agile response to market changes and customer needs.

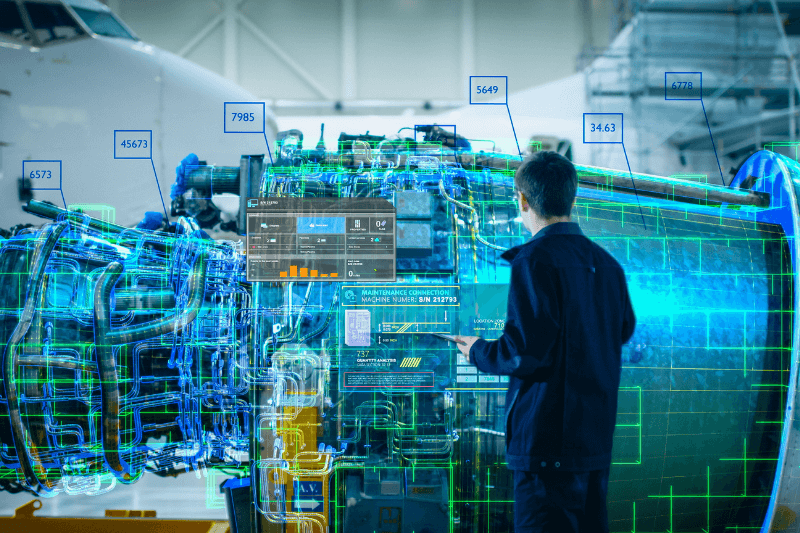

Augmented Reality (AR)

Augmented reality involves overlaying digital information onto the physical manufacturing environment. AR can be used through devices such as smart glasses, mobile apps or digital projection, allowing workers to view digital data, instructions, or images superimposed over the real-world setting. This technology enhances the interaction between digital systems and physical processes.

Impact: The impact of AR in manufacturing is significant, offering enhanced assistance in assembly, maintenance, and training. It leads to improved precision and efficiency in complex tasks, reduces errors, and provides real-time guidance and support to workers. AR also accelerates the training process, enabling new workers to quickly learn and adapt to their roles. In troubleshooting and maintenance, AR provides immediate, contextual information, reducing downtime and enhancing operational productivity.

Automation and Robotics

Automation and robotics are used to automate repetitive tasks, such as assembly and packaging, that require precision and consistency. Robots are capable of performing these tasks with a high degree of accuracy and speed, leading to improved efficiency and reduced labor costs.

Impact: The use of automation and robotics in manufacturing increases productivity by enabling manufacturers to produce goods at a faster rate, leading to higher output. It enhances precision as robots can perform tasks with a level of accuracy that is challenging to achieve manually, resulting in higher-quality products. It improves efficiency by automating repetitive tasks, which helps reduce waste and leads to cost savings. Lastly, automation and robotics enhance safety by enabling the performance of dangerous tasks, such as handling hazardous materials, thus improving worker safety.

Additive Manufacturing and 3D Printing

Additive manufacturing and 3D printing refer to the process of creating objects from 3D model data by layering material. This technology enables the production of complex shapes and structures that would be difficult or impossible to achieve with traditional manufacturing methods.

Impact: Additive manufacturing and 3D printing have revolutionized the manufacturing industry by offering unprecedented design freedom and customization. This technology allows for rapid prototyping, reduced material waste, and the creation of lightweight, durable parts. Additionally, additive manufacturing and 3D printing have the potential to decentralize production and reduce the environmental impact of manufacturing processes.

Blockchain

Blockchain technology refers to a decentralized, distributed ledger that records transactions securely across many computers. This ensures that recorded data cannot be altered retroactively, offering an elevated level of security and transparency.

Impact: In manufacturing, blockchain can greatly enhance supply chain transparency and traceability. It provides a reliable and tamper-proof way of recording the production, transportation, and delivery of products. This transparency is crucial for quality assurance, compliance, and for building trust with customers and suppliers. Additionally, blockchain can streamline transactions and contractual processes with suppliers, reducing administrative costs and increasing efficiency. The technology’s ability to securely and transparently handle data makes it an invaluable tool in the modern manufacturing landscape.

Each of these technologies contributes uniquely to the smart factory ecosystem, enabling manufacturers to achieve unprecedented levels of precision, efficiency, and quality. As these technologies continue to evolve and integrate, the potential for innovation in smart manufacturing becomes virtually limitless.

Benefits of Transitioning to a Smart Factory

Transitioning to a smart factory model brings crucial benefits to modern manufacturing:

- Increased Operational Efficiency: Integration of IoT, AR, AI, and machine learning leads to streamlined processes, reducing downtime, increasing output, and enhancing productivity.

- Enhanced Product Quality: Digital twins, AR, and real-time, AI-driven quality control systems ensure higher accuracy and consistent product quality.

- Production Customization and Flexibility: Additive manufacturing allows for greater flexibility in design and production, catering to specific customer needs.

- Sustainability: Efficient resource management leads to reduced waste and energy consumption. For example, cloud connectivity and big data analytics optimize resource utilization, leading to significant cost and energy savings.

- Improved Safety and Compliance: Advanced monitoring and predictive analytics coupled with AR contribute to safer workplace environments and adherence to regulatory standards.

The Four Evolutionary Stages of Smart Factories

Stage One: Basic Data Collection

At this foundational level, factories begin to digitize data, making it accessible but not yet fully utilized. It involves the collection of data from various sources like machinery, inventory, and workforce. The key here is the shift from paper-based to digital records, laying the groundwork for more sophisticated data use.

Level Two: Proactive Data Analysis

Factories at this level not only collect but also start to analyze data proactively. This involves basic analytics to understand production trends, equipment efficiency, and potential bottlenecks. It’s a step towards data-driven decision-making, where insights are used to optimize processes.

Level Three: Real-Time Data Utilization

Here, data is not just analyzed; it’s used in real time to drive operations. This level sees the integration of IoT and cloud computing, enabling live monitoring and adjustments. It’s about responsive and dynamic process management, where data actively informs decisions and guides operational processes, like digital work instructions.

Related Content: Digital Work Instructions: The Ultimate Guide

Level Four: Predictive Data for Autonomous Decision-Making

At the pinnacle, factories become fully integrated smart ecosystems. Data is not just for insight but for autonomous action. Advanced AI algorithms predict issues and initiate solutions without human intervention, leading to a highly efficient, self-optimizing manufacturing environment.

Challenges and Considerations

Although advantageous, the shift to smart manufacturing presents several challenges requiring careful consideration:

- High Initial Investment: Implementing smart factory technologies requires significant capital investment in new equipment and training.

- Cybersecurity Risks: The increased reliance on digital systems makes factories more susceptible to cyber threats and data breaches.

- Complexity in Integration: Merging modern technologies like blockchain and IIoT with existing systems can be complex and require skilled expertise.

- Workforce Skill Gap: There is a need for upskilling employees to handle and manage these advanced technologies effectively.

- Reliability and Maintenance: Ensuring the reliability of these sophisticated systems and their maintenance can be challenging.

Real-World Use Cases and Success Stories

This section dives deeper into case studies from industry giants like Siemens, Bosch, and L3Harris Technologies. We’ll explore their implementation strategies, challenges faced, and the powerful outcomes of adopting smart manufacturing practices.

Siemens’ Amberg Electronics Plant: Revolutionizing Manufacturing through Digital Integration

Siemens’ Amberg Electronics Plant (EWA) exemplifies the future of manufacturing. This facility has become a global benchmark in integrating advanced automation with digital technologies. The plant is a clear demonstration of how the fusion of the real and virtual worlds can revolutionize the manufacturing process, making it more efficient, flexible, and intelligent. To achieve this, key smart factory solutions were implemented by Siemens:

- Real and Virtual World Integration: Merging physical manufacturing with digital technology for seamless operations.

- Direct Communication Between Products and Machines: Facilitating a self-regulating manufacturing process.

- Sophisticated IT Systems for Process Optimization: Ensuring all production processes are optimally integrated and controlled.

- Automated Material Transportation: A fully automated logistics system from warehouse to production line.

- High Level of Automation in Production: 75% of the production process is automated, with minimal human intervention.

Results:

- Increased Operational Efficiency: Achieved an eightfold increase in production volume without expanding the facility’s footprint or workforce significantly.

- Exceptional Quality Standards: Maintained a remarkably low defect rate of 0.0012%, resulting in 99.9988% production quality

- High Production Output: Approximately 15 million Simatic products manufactured annually, averaging one unit per second.

- Customization Capabilities: Ability to produce over 1,000 different product variants, showcasing exceptional flexibility in manufacturing.

Bosch’s Homburg Plant: Embracing Industry 4.0

Bosch’s factory in Homburg, Germany, faced the challenge of improving efficiency and reducing costs while maintaining flexibility in its hydraulic valve production line. The line is responsible for producing six main valve product types, with 250 variants and 2,000 individual parts. To achieve this, Bosch implemented several Industry 4.0 solutions:

- Autonomous Intelligent Workstations: Nine workstations were set up, capable of quickly switching between products.

- Active Assist Assembly Technology: This technology incorporates guided assembly steps using pick-to-light systems and verification with a 3D camera.

- RFID (Radio Frequency Identification) Integration: Each product is tagged with RFID, allowing for real-time monitoring of component positions and ensuring correct part selection.

- Customized Worker Assistance: The system recognizes employees via Bluetooth tags, providing instructions tailored to their qualification level and preferred language.

Results:

- Logistics and Set Up Time Reduction: From 450 seconds (about seven and a half minutes) to zero in one year.

- Inventory Efficiency: Inventory days were halved.

- Cycle Time Reduction: An 8% decrease in cycle times.

- Cost Savings: The plant saved €500,000 in the first year alone.

L3Harris Technologies’ Rochester, NY: Advancing with Smart Manufacturing Cell

L3Harris Technologies, facing increased customer demand for their tactical radios, needed to enhance production efficiency at their JROC facility. This demand for advanced technology was stretching their manufacturing capabilities to the limit.

L3Harris established a new Smart Manufacturing Cell to meet these escalating production demands. This Industry 4.0-level assembly process integrates various control technologies:

- Augmented Reality: Real-time work instructions, operator assembly guidance, and quality confirmation powered by LightGuide projection-based AR.

- A Common Industry-4.0 Platform: WorkSmart Systems integrated Cognex machine vision inspection and Mountz precision torque drivers into a common platform.

- Line-Agnostic Stations: Capable of building different products with the same process without needing device-specific configurations for different production lines.

- Data Collection and Analysis: The system records detailed data for troubleshooting and quality control.

Results:

- Efficiency Improvements: JROC’s tactical radio Focus Factory now runs three product lines simultaneously with increased efficiency.

- Reduced Non-Value-Added Time: The Smart Manufacturing Cell streamlines production, reducing time spent on activities like transporting parts across the manufacturing space.

- Cognitive Ergonomics: The system reduces mental fatigue and allows for controlled access based on training requirements, thereby enhancing quality control.

- Space Utilization and Safety: Streamlining processes has led to better space utilization and a safer work environment.

Future of Smart Manufacturing

The smart manufacturing horizon continually expands, marked by groundbreaking innovations:

- Cloud Computing: Pivotal for data storage, processing, and management, enhancing scalability, flexibility, and efficiency in manufacturing operations.

- Big Data: Relies on effectively collecting, processing, and analyzing vast datasets to extract insights and drive efficient practices across machinery performance, production rates, quality control metrics, and supply chain operations.

- Industrial Internet of Things (IIoT): Integrates sensors, machines, and devices for data collection and exchange, enhancing connectivity and efficiency from the supply chain to the production floor.

- Digital Twins: Create virtual replicas of physical systems, continuously updated for real-time simulation, analysis, and optimization of manufacturing processes.

- Artificial Intelligence: Simulates human intelligence processes to automate tasks, enhance decision-making, and optimize production processes.

- Machine Learning (ML): Enables systems to learn and improve from experience without explicit programming, analyzing data to make informed decisions.

- Augmented Reality (AR): Overlays digital information onto the physical manufacturing environment, enhancing interaction between digital systems and physical processes.

- Automation and Robotics: Utilized extensively in smart manufacturing, automation and robotics streamline production processes, enhance precision, and improve efficiency, leading to increased productivity and cost savings.

- Additive Manufacturing and 3D Printing: Create objects from 3D model data, enabling the production of complex shapes and structures difficult or impossible to achieve with traditional methods.

- Blockchain Technology: A decentralized, distributed ledger records transactions securely, ensuring data cannot be retroactively altered, providing security and transparency.

- Increased Focus on Sustainability: Smart factories lead in sustainable, energy-efficient, and eco-friendly manufacturing practices.

Smart Factories that Elevate Human Potential

Can we envision a manufacturing future where technology not only assists but elevates human potential? The path to smart manufacturing is a journey of evolution, vital to the industrial sector’s progression. It represents the perfect harmony of advanced technology and human ingenuity, enhancing efficiency, quality, and innovation.

As technologies like AI, ML, AR, IoT, and blockchain mature, the role of smart factories in reshaping manufacturing becomes increasingly significant. This change is not solely about staying ahead in the race; it’s about redefining the very essence of manufacturing for future generations.

Ready to Explore How Projected AR Work Instructions Can Give Your Workforce a Competitive Advantage?

Connect with our team to see how the LightGuide platform can transform your operations.